Abstract

Wind power is one of the major players in the renewable energy discussion. It is usually harnessed using large turbines with massive rotor blades in order to harness the mechanical energy of the wind. This movement is used to turn a magnetic field within the generator, causing a change in current. This paper discusses the problems with the current style of turbine blades and possible redesigns. It considers portability, efficiency, as well as created waste in choosing the optimal design. An experiment was run using three different blade shapes: orthodox, toroidal, and hexagonal. Each was 3d printed with PLA, put in front of a hair dryer blowing air at 10 m/s at a set distance within a consistent mount, and had its rotations per minute measured. As rotation is the key factor in measuring a rotor’s ability, the only other metric tested was the weight of each design. The results of this study show that, of the tested types, a tessellated hexagon design is best in terms of the three metrics considered. It rotated over twice as many times as an orthodox rotor in the same timeframe. A toroidal design functioned as well, though it had problems in terms of transportability. The hexagonal design was chosen due to its benefits as a periodic tiling of a simple polygon.

Keywords: Wind turbines, Transportability, Efficiency, Renewable, Wind Energy, Rotor, Waste

1. Introduction

In the face of increased emissions for power generation exacerbating climate change, renewable energy sources are seeing more use, with one of those renewables being wind power. Besides solar, which is available anywhere, wind is the next most accessible power source, as it can be harnessed in both hilly regions as well as plains1. Turbines generally fall into two categories: vertical and horizontal2, and are usually found either inland or offshore, each having its benefits.

The two most common misunderstandings with wind power are the means of movement and the means of generation. Instead of simply being blown by the wind, rotor blades are built in the same shape as airplane blades to harness lift the same way they do3. Furthermore, electricity is generated within the relatively small chamber the turbine is attached to, where an electromagnetic field i rotated within a generator, thereby producing electricity4. This means that rotation is the most important factor.

Wind turbines are largely made out of a glass fiber/epoxy composite that is specifically designed to hold up to extreme weather5. This makes them long-lasting, but it also makes them very difficult to recycle. Because of this, rotor blades are usually dumped in landfills or simply incinerated. There is research into alternatives, but no major breakthroughs have been made.

Even dumping blades in landfills can be a problem in itself. Blades are too large to be crushed by most crushers and extremely difficult to transport to landfills. In places where land is valuable, it is even more of a problem, as no city wants to use its dump to contain large turbine blades. There are ways to crush rotor blades into small, somewhat usable pieces, but they require specialized equipment and are largely still in development6.

Wind power has a number of problems. First of all, turbine blades are troublesome to transport. Due to their shape and material, there is no way to break them down and assemble them on-site. This means that large trucks are required, limiting the locations where turbines can be built. There are no real alternatives to trucks to remedy this, as trains are limited in where they can go, and no other vehicle can hope to both hold a blade and be able to take it to the desired location.

However, there are currently efforts to solve these problems. Some companies are creating modular wind turbines that don’t have the above problem. They are smaller in size and come together with other pieces to make large turbines that have the same wind-facing area, without the large volume. However, so far, there hasn’t been much work done on modular turbines due to a lack of funding.

Another large factor is efficiency. Turbine blades have a side profile of an airfoil, the shape regarded as being the most aerodynamic. Modern rotor blades don’t use drag to catch the wind; instead, they rely on the lift generated by the airfoil shape for motion. It can be noted, however, that regardless of using wind or drag, they need lots of wind in order to function, meaning that the result is effectively the same.

To further go into the aerodynamics of wind power, it is important to note a number of factors. First of all, there is the Betz limit to think about, which says that the maximum amount of energy a wind turbine can convert is 59.3%. This is an important thing to keep in mind regarding the future of wind power. Secondly, all, the airfoil design is rather old compared to other renewables, having been developed in the 1970s⁷. They took inspiration from airplanes for their design, adding twists in order to better help the blades cut through the wind. And in response to degradation reducing efficiency, the design was further changed, tapered in certain locations in order to minimize the effect of wear caused by weather over time. That design is the one we use today.

Finally, there is the aspect of waste. Turbine blades can be used for upwards of 20 years, so they are not often replaced. But, in this more and more eco-conscious world, they will see more use, and replacements will be needed more often. A blade requires hundreds of tons of coal to be burned for its creation, releasing a large amount of CO₂ into the air. After the 20 years or so are up, the blade must be replaced due to wear and tear. They are usually kept in landfills or simply incinerated.

This study seeks to find a better option for turbines, taking into account all of the above factors. If there is a design that surpasses the orthodox 3-blade design, then it would at least be useful in some areas. Even if it is not perfect, it could be tweaked in order to fill some niche that the huge blades of today struggle with.

There are three types used (orthodox, hexagonal, and toroidal), each with its own benefits. Before continuing, it must be noted that this paper will only focus on small-scale model tests, not large-scale simulations. This means that the results of the tests cannot in good faith be directly applied to full-scale rotors, due to certain scaling laws like the Reynolds number and the Mach number. However, these tests can still give insight into possible alternatives for rotor design, which could be used to update or redesign current ones. Some more limitations of this study are that it does not measure the strength of each blade over a longer period, nor does it consider the difference in materials between the model blades and real ones. Full-scale turbines function under different circumstances from these model ones, so this data is not simply transferable to real rotors. The objective of these experiments is to gain information on alternative rotor designs with small-scale tests.

2. Methodology

| Blade type | Rotations per minute (rpm); Trial 1 | Rotations per minute (rpm); Trial 2 | Rotations per minute (rpm); Trial 3 | Mass (g) | Average Angular Velocity (rad/min) | Mass per piece (g/module) |

| Orthodox | 353 | 356 | 347 | 5 | 36.97 | 1.67 |

| Toroidal | 726 | 724 | 729 | 21 | 76.03 | 3.50 |

| Hexagonal | 731 | 723 | 727 | 38 | 76.13 | 0.60 |

Three types of blades were tested: an orthodox type, a toroidal type, and a hexagonal type.

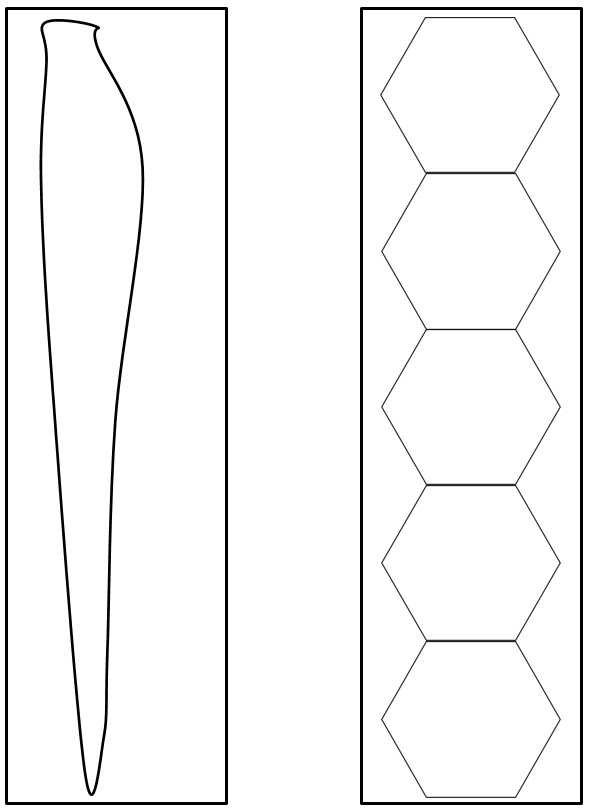

The orthodox design consists of 3 blades connected to a central base. Each blade has the side profile of an airfoil in order to generate lift in the face of the wind. Each also has a slight curve, which is in the direction it will turn. The hole in the center of the base is slightly larger than the width of the axle in order to have it fit through easily, due to earlier problems with loose plastic. It uses lift in order to rotate efficiently.

The toroidal design is an unorthodox design for a wind turbine, but is common in drones and RC vehicles. Toroidal propellers are known for being quieter and more efficient than regular ones. This one consists of 6 curved blades but was printed in one singular piece. Each individual curve is angled in order to push the wind more easily, though in this case, it acts as a surface for the wind to push.

The hexagonal design was included mostly out of interest. If made at scale, it would consist of far more pieces than the others, though each individual piece would be made individually, unlike in this version, where it is a single large piece. Each individual hexagon is slanted so as to better catch the wind. Of all of the rotor blades, this one has the simplest shape as it is just the same shape many times.

In the interest of fairness, each blade was kept at a diameter of 8 centimeters. Each was 3d printed with matte PLA filament and mounted on a similarly 3d printed axle and stand. PLA was used despite being different from the material of real rotor blades because this is a small-scale test. At this scale, the differences, like bending, are negligible. If this experiment were to test the durability of the rotors, then it wouldn’t be a suitable choice, but as that is not this experiment’s purpose, it doesn’t have a meaningful effect on the results. Next, a hair dryer was kept 8 inches from the center of the blade and used to blow air at each blade. Since this is done indoors, the starting wind speed is approximately zero. The hair dryer was measured to have a blowing speed of approximately 10 meter per second. A hair dryer was used due to ease of access in case others want to repeat this experiment, and its chaotic nature replicates the turbulent flow of real wind. After waiting 10 seconds for the blades to get up to speed, the recording began. A slow-motion camera was used to record the blades in motion. In the interest of ease of counting, a silver marking was placed at a point on each model blade. Afterward, the rotations were counted to approximate how well each model performed. This was done 3 times in total. Each blade was also weighed in order to gain an understanding of how much material would be needed. Finally, they would be compared based on those metrics as well as the possible benefits inherent to their designs.

3. Discussion

In terms of performance, the toroidal and hexagonal blades performed approximately evenly. The orthodox blade, however, didn’t even reach half the speed of the other two. In terms of mass, the orthodox blade is by far the lightest, followed by the toroidal and then the hexagonal. In terms of mass per piece, though, hexagonal was best, followed by orthodox, and trailed by toroidal.

The hexagonal type blade performed about evenly with the toroidal type, though it had much more mass. A difference between the hexagonal and toroidal blades is in their construction. The toroidal blade was, effectively, 6 large, curved blades stuck together. This would make it very difficult to transport at scale. The hexagonal, however, consists of 54 full hexes and 18 half hexes, tallying 63 in total.

If, for example, each hexagon was made individually and put together on site, that would solve the problem of transportation with orthodox blades. Note how even in this very basic figure above, the hexagons could be stacked to further increase transport efficiency. Furthermore, they don’t require transport trucks to be as large as orthodox blades. They could be made to slot together mechanically or welded together through other means. In transport, they could be stacked on trucks, resolving the issue of requiring special equipment. Heavy equipment would be needed at the location anyway to build the structure, so the same machinery could be used to put the hexes together. Some may have structural concerns, but those would be misplaced. Hexagons are noteworthy for their strong structure as force is spread across the whole plane. The most resilient material in the world, graphene, is similarly just a pattern of tessellated hexagons.

One limitation of this experiment is that it does not account for wear and tear over time. However, even without testing, the hexagonal-type design provides a simple solution. As it is a tessellated design, it consists of many modules. Simple checks could be performed periodically to check which pieces need replacement, and those could be switched out. Over time, this would produce less waste than replacing whole orthodox blades. On orthodox blades, wear on any part of a blade requires the whole thing to be replaced, while with this design, it would be possible to only replace the parts in dire need of replacement. Furthermore, since each piece would be smaller, they could be crushed by normal crushers and have their material reused for other purposes instead of lying around in landfills or waiting for specialized equipment.

This experiment functions well in replicating how a real turbine would function. Drag scales with area, so it can be understood that, if built, each blade type would perform similarly. The main reason that the orthodox type is used is because of transportation, not efficiency. In fact, to improve the hexagonal design, one could shape the edge of each hex to be an airfoil to make use of lift physics in the same way as an orthodox rotor blade.

It must be mentioned that, as a result of being smaller scale, this test also has a lower Reynolds’ number. This means that drag was higher and lift was lower than they would be for real turbines. If you were to scale these up, there’d likely be an inflection point where the orthodox model would equal or surpass the hexagonal or toroidal ones. The airfoil shape of the orthodox blade means that it functions based on lift, while the others use the drag from the wind to push themselves, so they are fundamentally different. Still, it must be noted that up to a certain point of increasing size, you’d likely see similar results to the ones from this experiment. Keep that in mind.

Despite all of its benefits, the hexagonal design was also the heaviest, as a result of having the most parts. This means that there could be some structural issues with the main structure of the turbine, making it unstable. This is a real issue, as the collapse of a turbine would lead to more damage to the environment and wasted funds. Furthermore, despite having the equipment, it would be difficult to put together 60+ modules on-site. Still, the solution lies in the modular construction. The hexagonal design might not be the best for full-scale turbines, but instead, it could find more success as a small-scale energy generator for buildings. They could use either smaller modules or simply fewer large ones. Smaller rotors wouldn’t need as large pillars; instead, they could be placed on top of buildings. Alternatively, there could be smaller-scale wind farms near residential areas, where land is too expensive to make larger turbines reasonable.

4. Conclusion

In conclusion, the hexagonal rotor blade isn’t perfect. It’s heavy, and as a result, it has a higher up-front cost. However, it is more easily transportable, repairable, and disposable than the mainstream. These characteristics are not minor or irrelevant. While not perfect for large wind farms, they could find use as small, renewable generators in the open areas of cities and towns, a niche that is currently uncontested.

References

- Where wind power is harnessed – U.S. Energy Information Administration (EIA). (2025). Eia.gov. https://www.eia.gov/energyexplained/wind/where-wind-power-is-harnessed.php [↩]

- How Do Wind Turbines Work? (2025). Energy.gov. https://www.energy.gov/eere/wind/how-do-wind-turbines-work#:~:text=Wind%20turbines%20can%20be%20built,wind%20deployment%20in%20U.S.%20waters. [↩]

- Special Enrollment Message. (2023). UTI Corporate. https://www.uti.edu/blog/wind-turbine/wind-turbine-math-physics [↩]

- How electricity is generated – U.S. Energy Information Administration (EIA). (2025). Eia.gov. https://www.eia.gov/energyexplained/electricity/how-electricity-is-generated.php#:~:text=In%20a%20turbine%20generator%2C%20a,the%20rotor%20to%20electrical%20energy. [↩]

- Wind Turbine Blades: Options at End of Life. (2024, September 18). Kleinman Center for Energy Policy. https://kleinmanenergy.upenn.edu/commentary/blog/wind-turbine-blades-options-at-end-of-life/ [↩]

- Unfurling The Waste Problem Caused By Wind Energy. (1970). NCPR; North Country Public Radio. https://www.northcountrypublicradio.org/news/npr/759376113/unfurling-the-waste-problem-caused-by-wind-energy [↩]