Abstract

With the never-ending development of global infrastructure today, ensuring the sustainability of transportation is paramount. This research paper strives to recognize where we can find a feasible solution for this problem. With the understanding that the current gasoline used to power everyday vehicles is limited, this paper examines how current vehicles running on petroleum can be converted into alternative fuel types, such as electricity. Through an investigation of already published research papers, this paper compiles a vast amount of information into terms that the common man can understand. The components of both gas-powered and electric-powered cars are identified, the conversion process is defined, the cost of the conversion is described, and the barriers and regulations are presented. This paper concludes that although there are efficiency problems with the conversion, it is overall a better resolution due to the finite resources to sustain gasoline and the harm it does to the environment, and with the elimination of the minor setbacks, this idea can be widely utilized for the benefit of the transportation industry.

Introduction

In recent years, pollution has increasingly worsened, and one of the main factors is that the most common form of transportation runs on internal combustion engines, which involve carbon emissions. “According to The World Bank, the transport sector is responsible for almost 64% of the global oil consumption and 23% of the energy-related CO2 emissions”1. Fossil fuels are a huge factor in the energy provided for the population, as “internal combustion (IC) engines operating on fossil fuel oil provide about 25% of the world’s power”2.

This paper seeks to understand what gas-powered cars are, what electric-powered vehicles are, and how to convert from one to the other to limit the damage that they are doing to the environment. This paper is dedicated to evolving the automobile industry and was inspired by a love for cars. It maintains that vehicles that run perfectly and are in pristine condition should not go to waste just because the world is changing, and as such, conversion presents itself as a necessary endeavor.

Gas-powered cars run on an internal combustion engine (ICE), which uses fuel and oxygen to run. When the fuel is consumed, emissions are pumped out, which consist of harmful chemicals such as carbon dioxide, methane, and nitrous oxide3. ICEs run on fossil fuels, which are limited in their supply. Only a select amount of these fossil fuels are available on earth for humans to use, and there are no ways to reuse or recycle them. Due to the modern world, fossil fuels are depleting at an extremely rapid pace beyond repair. A Stanford study shows the trend of fossil fuels, estimating that oil will be fully consumed by 2052, gasoline by 2060, and coal by 20904. Due to these reasons, the conversion of vehicles that run on ICEs to electric vehicles (EVs) is especially necessary. “Even though the consumer preferences for EVs vary based on a mix of symbolic, environmental, economic, and pro-societal benefits, there is a dearth of research capturing the widespread gamut of factors related to EV adoption”5. An EV functions much differently from an ICE. Rather than running on fuel like the ICE, an EV has a complex battery that can be charged and powers the electric motor of the car, giving power for the car to run. EVs have become more and more common in the vehicle industry, but they are built from the ground up using new parts, not with already existing vehicles. The building of new EVs overlooks the existence of already functional vehicles, potentially causing millions of dollars to go to waste. To fix this, a method to convert ICEs to EVs is compulsory.

This research paper embarks on a voyage to explore and create a practical, cost-effective solution for converting ICE automobiles into EVs, which serves as a necessary development for the

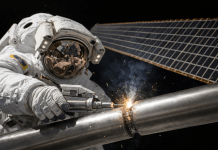

future of this industry. Our investigation considers the many challenges associated with such a transformation, including technological feasibility, economic viability, and regulatory considerations. By diving into these complexities and proposing a well-structured approach, this study seeks to provide insights that can help create a sustainable automotive landscape. This study will include in-depth explanations, photos, and diagrams of many different mechanical parts. Since the eventual goal is to implement this idea into the real world and have it be of great use, we will look at laws, regulations, and safety concerns regarding conversion methods. This research is solely based on internet research and is put together completely virtually. A real-life experiment cannot able to be done because of the risks and factors behind it. The final goal of the project is to have a detailed enough explanation that, with the right materials, budget, and time, can be carried out and worked in the real world.

Background

Comparison of an internal combustion engine and an electric motor Internal combustion engine:

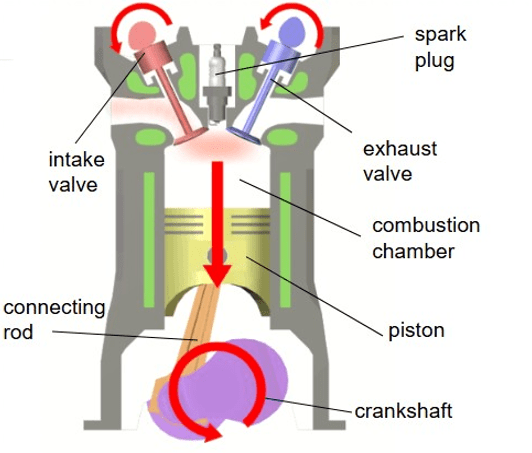

The internal combustion Engine (ICE) is a machine that is most commonly found in gas-powered cars. It is a type of heat engine that generates power by burning fuel in a chamber; Figure 1 shows the four-stroke cycle, the most common7. It acts as the powerhouse of the car, letting it do all the things needed to run. The ICE needs three things to work: fuel, a spark, and air. The ICE has many different components located throughout the car7. The process starts off with the fuel being injected into the combustion chamber directly from the fuel line through the fuel injector. The fuel is mixed with air and is inducted into the cylinders, where the pistons compress the mixture. Then, the spark plug ignites the fuel, causing combustion, which the crankshaft converts to power that the wheels use to spin. The process produces fumes that exit the car through the exhaust system. More cylinders in the engine mean more pistons, which creates more power. Older vehicles use a carburetor, which controls and mixes air, but was replaced in the 90s by the fuel-injection system, which does the process more precisely and efficiently. Key components include:

Cylinders: The cylinder is the combustion chamber where the air-fuel mixture ignites, generating high-pressure gases to drive the piston. It is precisely machined within the engine block and made from cast iron or aluminum alloys to withstand extreme temperatures and pressures. The number of cylinders in an engine affects power output, fuel efficiency, and smoothness, with configurations like inline-4, V6, and V8 being common.

Piston: The piston is a cylindrical component that moves up and down inside the cylinder, converting combustion energy into mechanical force. It connects to the crankshaft via a connecting rod, transforming reciprocating motion into rotational motion. Made of lightweight aluminum alloys, pistons also feature piston rings to maintain a tight seal and reduce friction between the piston and cylinder wall.

Crankshaft: The crankshaft converts the linear motion of the pistons into rotational motion, which powers the vehicle’s drivetrain. It consists of main journals, rod journals, and counterweights to balance forces and ensure smooth engine operation. Made from high-strength forged steel or cast iron, the crankshaft is supported by bearings to minimize friction and enhance durability.

Valves: Valves regulate the entry of the air-fuel mixture into the cylinder and the exit of exhaust gases. Intake valves open during the intake stroke to allow fresh air or an air-fuel mixture to enter, while exhaust valves open after combustion to release gases. Controlled by the camshaft, valves operate with precision, and modern engines use variable valve timing (VVT) to optimize efficiency and performance.

Spark Plug: The spark plug ignites the compressed air-fuel mixture by generating a high-voltage electric spark between its electrodes. It consists of a center electrode, a ground electrode, and a ceramic insulator, all designed to withstand high temperatures and pressures. Advanced spark plug materials, such as iridium and platinum, provide better ignition performance and longer lifespan.

Carburetor: The carburetor is responsible for mixing fuel and air in the correct ratio before it enters the combustion chamber. It operates using the Venturi effect, where air velocity increases in a narrow passage, drawing in fuel from a jet. Though once common, carburetors have been largely replaced by electronic fuel injection (EFI) systems, which offer better fuel efficiency and emissions control. The carburetor is omitted in newer engines in the 21st century due to high carbon emissions, and is replaced with fuel injection systems that precisely inject the amount of fuel into the air and mix it straight into the combustion chamber8.

Electric Motor

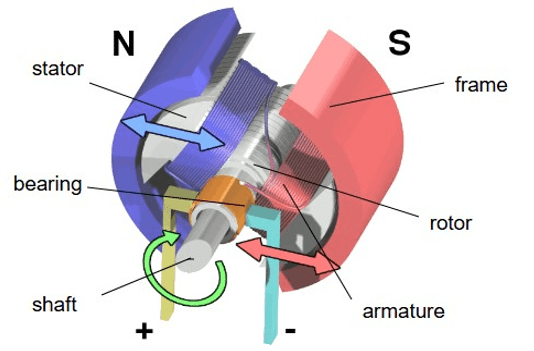

The electric motor is fundamentally different from an internal combustion engine (ICE), offering superior efficiency, reduced maintenance requirements, and cost-effectiveness over time. Unlike an ICE, which converts chemical energy from fuel into mechanical energy through combustion, an electric motor operates by converting electrical energy from a battery into mechanical motion using electromagnetic principles. This allows for instantaneous torque delivery, smoother acceleration, and a significantly higher energy conversion efficiency. Electric motors eliminate the need for complex ICE components such as pistons, crankshafts, and camshafts. Instead, they rely on electromagnetic fields to generate motion. The core working principle is based on Maxwell’s equations

Faraday’s Law – ![]()

Ampère’s Law – ![]()

Gauss’s Law for Electricity – ![]()

Lorentz Force – ![]()

![]()

The fundamental idea that Maxwell’s equations lay out, is the way electric

and magnetic fields interact through electromagnetic waves10.The electric motor functions through the interaction between a stationary magnetic field and a rotating magnetic field, which is being fueled by electricity, as described through Faraday’s law of induction, leading to continuous motion11.

The key components of an electric motor are:

Stator: The stationary part of the motor, consisting of laminated iron cores and copper windings. When current flows through the windings, it generates a rotating magnetic field, which induces motion in the rotor. In AC motors, the stator receives three-phase alternating current (AC), while in DC motors, it is powered by direct current (DC) and often works with a commutator.

Rotor: The rotating component of the motor, typically containing permanent magnets (in Permanent Magnet Synchronous Motors, PMSM) or electromagnets (in induction motors). The interaction between the rotor’s magnetic field and the stator’s field generates torque, enabling motion.

Shaft: The rotor is mechanically coupled to a shaft, which transmits rotational energy to the vehicle’s drivetrain. In direct-drive configurations, the shaft directly connects to the wheels, while in some cases, a reduction gearbox optimizes torque and speed distribution.

Winding: The copper wire coils within the stator are responsible for carrying the electrical current that generates the electromagnetic fields. Their arrangement influences efficiency, torque output, and heat dissipation. Advanced designs incorporate liquid cooling systems or specialized insulation materials to manage thermal performance and enhance durability12.

Electric motors can be classified into different types based on their operating principles, such as:

- Permanent Magnet Synchronous Motors (PMSM) – Used in most modern EVs, offering high efficiency and power density.

- Induction Motors (IM) – Used in early Tesla models, relying on electromagnetic induction rather than permanent magnets.

- Switched Reluctance Motors (SRM) – Known for durability and efficiency, but less commonly used due to control complexities.

For now, and through intensive research, induction motors are the most tested and most reliable.

Methodology:

The process of converting an ICE to an EV

What needs to be done to convert from an ICE operating system to an EV operating system is simple, but the process is extremely difficult. Essentially, all the components that are in an ICE need to be removed, including the wires and materials that connect to it, so the entire engine bay needs to be cleared, almost the entire underside that has pipes and valves need to be cleared, and fixated, the wheels need to be re-programmed, and the fuel tank and the area around need extreme work. Those are the main steps, but changes need to be made within the car’s interior as well, as it needs to accommodate the car’s computerized systems, meaning that fuel gauges and other essential notifications and systems must be adjusted. Safety features then need to be remodeled to work around the new fuel type of the car. This maps out a specific, simple plan, but carrying out these actions requires precise technique. Since we are removing almost every component of the car, we need to fill it up with something else, otherwise, it could be dangerous to passengers. This process will also be costly as the replacement parts of an electric vehicle are much more expensive, harder to find, and harder to install.

EV Constitutive Elements

- Electric motor

- Energy Storage System (batteries)

- Shaft

- Controllers

Cost of Conversion

The cost of the conversion is where the numbers get high. The cost of the battery itself is anywhere between $4,000-$20,000. After that, integrating it within the gas car, taking out its components, and installing the rest of the electric vehicle parts can increase the price to well over $35,000.

| Individual Parts | Battery | Motor | Shaft | Total: | Cost of Electric Car (Available in the USA only and road-legal as of October 2024) |

| Minimum Cost (in USD): | $4000 | $1500 | $1000 | $6500 | $29,280 – Nissan Leaf |

| Maximum Cost (in USD): | $20000 | $6500 | $8000 | $34000 | $422,750 – Rolls-Royce Spectre |

Conversion Kits

Conversion kits are the main method for the commercial production of this shift in fuel type.

Some companies are already moving forward in this. Current EV Motors, a company located in Austin, Texas, is working on conversion kits that can be implemented into older Ford models. By creating an affordable and market-available conversion kit, the product is more accessible to the consumer base14. This method is very affordable and useful, being the easiest way for a conversion to happen.

Electric Vehicle Adoption Barriers

Electric vehicles are environmentally friendly, but they still result in problems that do not allow for the full potential of the conversion. The biggest issue is the range of EVs. It is well known that electric motor technology is fairly new, and accordingly, the distance on a full charge is nowhere close to gas-powered cars. This makes it harder for EVs to become popular in areas that do not have as many charging stations and power, negating all of their potential benefits. This also ties in with the next problem, which is the time it takes to charge EVs. Even if the vehicle’s range was limited, extremely quick charging times would mitigate any inconvenience; however, this is not the case. The average charging time for an electric road vehicle is fifteen to twenty hours, which is extremely long and creates a huge barrier to its efficiency. On the other hand, it only takes about two minutes to fill up a car with gas. To increase the popularity of conversion, the charging times of electric vehicles would have to decrease drastically, while preserving or increasing their range. This is already being experimented with in vehicles where energy from the brakes is converted into energy for the car to drive; if electric vehicles could charge their batteries while running, that could completely change the EV market. Another issue that hinders the production of EVs is the economic status, the availability of the parts, and the fluctuating sales that cause huge defects. This can be dealt with, though, with alternative parts and sellers to diversify the production. Those being the biggest issues have the most need to be resolved to implement this conversion. There are also other smaller issues related to EVs, such as political problems, where certain regions do not allow the purchasing or production of electric vehicles. Although there are these issues with the conversion to electricity, they are still extremely manageable, and there are workarounds that still allow for it.

Regulation guidelines for EV conversion

Converting a gasoline-powered vehicle to an electric vehicle (EV) in the United States is a technically and legally complex process due to safety, emissions, and regulatory requirements. Regulations vary by state and evolve over time, making it essential for vehicle owners and conversion professionals to stay informed about compliance standards. At the federal level, the National Highway Traffic Safety Administration (NHTSA)15 governs vehicle safety standards, while the Environmental Protection Agency (EPA)16 enforces emissions regulations. Additionally, state-level agencies, such as the California Air Resources Board (CARB)17, impose further compliance requirements.

Failure to meet these standards will result in registration denial, fines, or even restrictions on vehicle use. Consequently, understanding these regulatory frameworks is critical to ensuring a successful, legal, and safe conversion.

Safety Standards

EV conversions must adhere to federal motor vehicle safety standards (FMVSS)15, which govern aspects such as structural integrity, crashworthiness, braking performance, and high-voltage system safety. The integration of high-voltage lithium-ion battery packs introduces additional risks, including electrical fires, thermal runaway, and short circuits, necessitating compliance with established industry standards such as:

SAE J2344 – Safety guidelines for electric and hybrid vehicle propulsion systems18.

SAE J2578 – General safety requirements for battery-electric vehicles18.

UL 2580 – Safety testing requirements for lithium-ion battery packs used in EVs19.

NFPA 70E – Electrical safety standards to mitigate arc flash and shock hazards20.

One of the biggest challenges of conversions is integrating a high-voltage system into a chassis originally designed for an internal combustion engine (ICE). Unlike OEM-designed EVs, converted vehicles lack engineered crumple zones for battery protection, increasing fire and impact risks in the event of a crash21. Furthermore, improper battery mounting can lead to weight distribution issues, affecting handling and suspension performance22.

To address these risks, professional engineering expertise is essential in designing a robust enclosure for battery modules, implementing cooling systems, and reinforcing vehicle structures to accommodate additional weight23. However, these safety measures often introduce higher costs and engineering complexity, making compliance a barrier for DIY enthusiasts without access to advanced fabrication tools.

Electric Vehicle Safety Standards

Beyond general safety, specific regulations govern the installation and operation of high-voltage electrical systems, including:

SAE J1772 – Standardized charging connector and communication protocol for Level 1 and Level 2 charging24.

ISO 6469 – Safety requirements for onboard electrical systems, including insulation resistance and fault protection25.

IEEE 1725 – Battery safety and performance standards26.

Proper wiring, insulation, and battery management systems (BMS) are required to prevent overcharging, overheating, and short circuits19. Additionally, ground fault detection systems must be incorporated to minimize shock hazards20.

A major challenge in EV conversions is ensuring that the electrical system integrates seamlessly with the vehicle’s chassis and powertrain components22. Unlike purpose-built EVs, converted vehicles often require custom wiring harnesses and additional insulation to prevent electrical faults21. Poorly designed or improperly installed high-voltage components pose severe risks, including electrocution hazards during maintenance and increased fire risks in the event of a collision19.

From a regulatory standpoint, many states lack clear guidelines on high-voltage system certification27, leaving interpretation open to local DMV officials. This regulatory gap creates inconsistencies, making it difficult for EV converters to know exactly what modifications are required for approval15.

Emission Compliance

While electric vehicles produce zero tailpipe emissions, converted EVs must still undergo regulatory scrutiny to ensure compliance with emissions and efficiency standards16. Some of the key considerations in the United States include the following regulations:

Environmental Protection Agency(EPA) Certification – Converted vehicles must meet EPA approval for emissions exemption and cannot exceed manufacturer-stated pollution limits (e.g., vapor emissions from remaining fuel system components)16.

California Air and Resources Board(CARB) Compliance (California & Other ZEV States) – CARB mandates that all vehicle modifications, including ICE-to-EV conversions, comply with the state’s strict Zero Emission Vehicle (ZEV) regulations27.

Battery Recycling & Disposal Regulations – The EPA requires proper disposal of lead-acid or lithium-ion batteries, with penalties for improper disposal16.

A key issue for regulators is the verification of emissions compliance in converted vehicles. Since these vehicles were not originally designed as EVs, regulatory agencies must confirm that all fuel-related components (e.g., fuel tanks, exhaust systems) are fully removed to eliminate vapor emissions17.

Additionally, CARB’s stringent certification process for EV conversions has made it difficult for independent converters to legally register vehicles in California without undergoing costly third-party testing at an EPA-certified laboratory17. This regulatory burden disproportionately affects DIY converters and small EV conversion shops, limiting innovation in the industry28.

Vehicle Inspections

Before an EV conversion can be legally driven, it must pass state-mandated safety and emissions inspections15, which include a brake system assessment, ensuring proper braking force with regenerative braking integration21. A structural integrity check – Verifying modifications to support new weight distribution and battery mounting22. Lastly, a lighting and electrical system inspection – Ensuring high-voltage components meet safety requirements19

Vehicle inspections introduce state-by-state variability, making it difficult for conversion enthusiasts to predict what modifications will be deemed acceptable15. In states with rigorous testing procedures (e.g., California, New York, Massachusetts), converted vehicles may need additional certification, increasing conversion costs and time17. Conversely, states with lax inspection standards may inadvertently allow unsafe conversions, creating potential hazards for drivers and other road users28.

Title and Registration Updates

Converted EVs must have their titles and registrations updated to reflect the new fuel type and propulsion system15. In order to be registered, they require a DMV Certification, an updated

VIN Classification, and insurance Considerations

The lack of standardized federal guidelines for EV conversions results in bureaucratic challenges when updating vehicle records15. In some states, vehicle owners may struggle to obtain accurate insurance coverage due to insurers’ unfamiliarity with converted EVs17.

While ICE-to-EV conversions provide an exciting path toward sustainable transportation, they also introduce significant regulatory, financial, and technical challenges. The lack of standardized conversion laws across states creates uncertainty for builders, while stringent safety and emissions regulations increase compliance costs28. As EV adoption grows, policymakers may need to simplify and clarify conversion regulations to promote broader adoption and support innovation within the conversion industry15.

Vehicle Charging

The current EV charging infrastructure in the United States is concentrated on the East Coast and the Far West, with significant gaps in central and rural areas, as highlighted in Figure 5. While regions like California and the Northeastern states have dense charging networks, many areas in the Midwest and South lack sufficient stations. This disparity presents a challenge for EV adoption, as it limits the convenience of long-distance travel and increases the risk of “range anxiety”29. Efforts to address this include government initiatives like Electrify America and private investments from companies such as Tesla, aiming to expand charging networks to underserved areas and highways and promoting accessibility and convenience30.

Charging times, which can range from 8 to 12 hours for a full charge, remain a major obstacle for EV owners, particularly in a fast-paced world where quick turnarounds are crucial29. Although DC fast chargers are available and can significantly reduce charging time to about 30 minutes to 1 hour, their availability is limited, especially in rural areas31. Ongoing efforts to improve charging infrastructure and invest in faster-charging technologies, along with federal initiatives like the Infrastructure Investment and Jobs Act, are expected to address these gaps32. As EV adoption grows, increasing the density and efficiency of charging networks will be essential for supporting long-distance travel and ensuring that EVs become a practical choice nationwide. The expansion of these networks will also be crucial in meeting future Zero Emission Vehicle (ZEV) mandates, especially in regions where charging access is currently insufficient32.

Results:

The future of electric vehicles

The future of electric vehicles is extremely promising, with the sustainability of the fuel type. The change in our climate and the reliability of electricity are huge factors in the positive growth of electric vehicles. With the increase in market availability and advancing infrastructure, electric cars are going to make a huge impact on the future of the vehicle industry. The emergence of fast-charging stations and the spread to rural areas of the world are leading to this feat. The innovation of lithium-sulfur and solid-state batteries is increasing energy levels and lowering charging time, which is crucial for the implementation of this system34. The change from gas to electricity is necessary due to the dependence of our future on electricity.

Limitations

The limitations for the conversion of Gas-powered vehicles to become mainstream are the efficiency and the price tag. Extremely high prices are required for this conversion, and running on electricity, with longer charging times and lower range, falls far behind the efficiency of gasoline. The main workaround to make this method widespread is to make clear the limited resources for gasoline and fossil fuels. This realization will help increase the popularity of electric-powered vehicles to make this conversion much more possible. The price is very costly, but because the vehicle is already structured and an entirely new car does not need to be built, it would be more cost-effective to convert directly. It also reduces waste, especially when gasoline cars are in perfect condition. When looking into all the factors, it would be much more beneficial, especially short to invest in these types of vehicle conversions, because gasoline is limited and will not be sustainable very soon.

Conclusions

Fuel conversion is increasingly recognized as a crucial step toward energy sustainability. However, widespread adoption faces challenges related to cost, efficiency, and infrastructure limitations. The high costs associated with EV conversions, along with longer charging times and lower range compared to gasoline vehicles, have slowed mainstream adoption. Despite these concerns, the finite nature of fossil fuel resources and the growing push for cleaner energy solutions highlight the necessity of transitioning to electric power. As battery technology advances and economies of scale drive down costs, conversion feasibility will improve, making it a more viable option for consumers seeking a sustainable and cost-effective alternative.

One of the key advantages of conversion is that it repurposes existing vehicle structures, reducing overall costs compared to manufacturing a new EV from scratch. This also minimizes waste, as many gasoline-powered vehicles in good condition can be retrofitted instead of being discarded. Additionally, government incentives and subsidies aimed at promoting electric mobility can help offset the financial burden of conversion, making it a more attractive option. As charging infrastructure expands and battery efficiency improves, converting gasoline cars to electric will become an increasingly practical and environmentally responsible choice. Given the inevitability of fossil fuel depletion and the rising demand for sustainable transportation, investing in EV conversions now will help accelerate the transition to a cleaner and more efficient automotive future.

References

- Krishna G, Understanding and identifying barriers to electric vehicle adoption through thematic analysis, 2021, Transportation Research Interdisciplinary Perspectives [↩]

- The Future of the Internal Combustion Engine, 2019, IJER editorial [↩]

- “Controlling Air Pollution From Motor Vehicles.” Department of Environmental Conservation, dec.ny.gov/environmental-protection/air-quality/controlling-motor-vehicle-pollution#:~:text=Car bon%20monoxide%2C%20nitrogen%20oxides%2C%20and,emit%20air%20and%20fuel%20res iduals [↩]

- MAHB. “When Fossil Fuels Run Out, What Then? – MAHB.” MAHB, 25 Aug. 2023, mahb.stanford.edu/library-item/fossil-fuels-run [↩]

- Kumar Rajeev, Alok Kumar, Adoption of electric vehicle: A literature review and prospects for sustainability, 2019, Journal of Cleaner Production [↩]

- File:Global Carbon Emission by Type.png – Wikimedia Commons. commons.wikimedia.org/wiki/File:Global_Carbon_Emission_by_Type.png [↩]

- The Editors of Encyclopedia Britannica. “Four-stroke Cycle | Definition, History, and Facts.” Encyclopedia Britannica, 24 Mar. 2023, www.britannica.com/technology/four-stroke-cycle [↩] [↩]

- Nice, Karim. “How Fuel Injector Systems Work.” HowStuffWorks, 29 Apr. 2024, auto.howstuffworks.com/fuel-injection.htm#:~:text=Direct%20injection%20systems%20have%2 0revolutionized,vehicles%20and%20certain%20niche%20applications [↩]

- File:Four Stroke Cycle power.png – Wikimedia Commons. 2004, commons.wikimedia.org/wiki/File:Four_stroke_cycle_power.png [↩]

- Kashy, et al. “Electromagnetism | Definition, Equations, and Facts.” Encyclopedia Britannica, 26 Mar. 2025, www.britannica.com/science/electromagnetism [↩]

- Wikipedia contributors. “Faraday’s Law of Induction.” Wikipedia, 18 Apr. 2025, en.wikipedia.org/wiki/Faraday%27s_law_of_induction [↩]

- A. Hughes and B. Drury, Electric Motors and Drives: Fundamentals, Types and Applications, 5th ed. Elsevier, 2019 [↩]

- Wikipedia contributors. File:Electric Motor Cycle 1.png – Wikipedia. en.wikipedia.org/wiki/File:Electric_motor_cycle_1.png [↩]

- “Home – Current EV Motors.” Current EV Motors, 5 Oct. 2023, currentevmotors.com. 1 [↩] [↩]

- National Highway Traffic Safety Administration (NHTSA), “Federal Motor Vehicle Safety Standards (FMVSS),” [Online]. Available: https://www.nhtsa.gov/laws-regulations/fmvss [↩] [↩] [↩] [↩] [↩] [↩] [↩] [↩]

- Environmental Protection Agency (EPA), “Regulations for Electric and Hybrid Vehicles,” [Online]. Available: https://www.epa.gov/regulations-electric-vehicles [↩] [↩] [↩] [↩]

- California Air Resources Board (CARB), “Zero Emission Vehicle (ZEV) Program Requirements,” [Online]. Available: https://ww2.arb.ca.gov/our-work/programs/zero-emission-vehicle-program [↩] [↩] [↩] [↩] [↩]

- Society of Automotive Engineers (SAE), “SAE J2344: Guidelines for Electric Vehicle Safety,” [Online]. Available: https://www.sae.org [↩] [↩]

- Underwriters Laboratories (UL), “UL 2580: Battery Safety Standards for Electric Vehicles,” [Online]. Available: https://www.ul.com [↩] [↩] [↩] [↩]

- National Fire Protection Association (NFPA), “NFPA 70E: Standard for Electrical Safety in the Workplace,” [Online]. Available: https://www.nfpa.org [↩] [↩]

- Automotive Engineering Journal, “Structural and Safety Challenges in EV Conversions,” vol. 15, no. 3, pp. 112-128, 2023 [↩] [↩] [↩]

- Institute of Mechanical Engineers (IMechE), “Weight Distribution and Handling Effects in EV Conversions,” [Online]. Available: https://www.imeche.org [↩] [↩] [↩]

- Electric Vehicle Association, “Regulatory Barriers to DIY Electric Vehicle Conversions,” [Online]. Available: https://www.myeva.org [↩]

- Society of Automotive Engineers (SAE), “SAE J1772: EV Charging Standards,” [Online]. Available: https://www.sae.org [↩]

- International Organization for Standardization (ISO), “ISO 6469: Electrically Propelled Road Vehicles – Safety Specifications,” [Online]. Available: https://www.iso.org [↩]

- Institute of Electrical and Electronics Engineers (IEEE), “IEEE 1725: Battery Safety Standard for Electric Vehicles,” [Online]. Available: https://www.ieee.org [↩]

- California Air Resources Board (CARB), “Zero Emission Vehicle (ZEV) Program Requirements,” [Online]. Available: https://ww2.arb.ca.gov/our-work/programs/zero-emission-vehicle-program [↩] [↩]

- Electric Vehicle Association, “Regulatory Barriers to DIY Electric Vehicle Conversions,” [Online]. Available: https://www.myeva.org [↩] [↩] [↩]

- U.S. Department of Energy, “Electric Vehicle Charging Infrastructure,” [Online]. Available: https://www.energy.gov/electric-vehicles [↩] [↩]

- Electrify America, “Charging Network Expansion,” [Online]. Available: https://www.electrifyamerica.com [↩]

- California Air Resources Board, “Zero Emission Vehicle Program,” [Online]. Available: https://ww2.arb.ca.gov/our-work/programs/zero-emission-vehicle-program [↩]

- Biden Administration, “Infrastructure Investment and Jobs Act,” [Online]. Available: https://www.whitehouse.gov [↩] [↩]

- Hanig, Lily, et al. “Finding Gaps in the National Electric Vehicle Charging Station Coverage of the United States.” Nature Communications, vol. 16, no. 1, Jan. 2025, https://doi.org/10.1038/s41467-024-55696-8 [↩]

- Wang, Daiwei, et al. “Realizing High-capacity All-solid-state Lithium-sulfur Batteries Using a Low-density Inorganic Solid-state Electrolyte.” Nature Communications, vol. 14, no. 1, Apr. 2023, https://doi.org/10.1038/s41467-023-37564-z [↩]