Abstract

In this paper, the author designed and developed an experimental platform that simulates a small house model. The insulation effects of different wall and window materials is tested to assess their potential for energy savings. Both steady state behavior and transient behavior were investigated. Three materials were studied: a single layer glass, a double layer glass and an insulation material. Under identical experimental conditions, insulation material exhibited a maximum steady-state temperature of 43.6 °C, whereas single layer glass maintained a markedly lower temperature of 19.9 °C and double layer glass stabilized at 33.0 °C, enabling a direct comparison among the three materials. Based on the experimental results, a recommendation to designers is provided and help designers choose the suitable energy efficient materials for various climatic conditions. This research not only provide guidance to the energy-efficient technologies but also provide a positive impact on the environment.

Keywords: Energy Consumption, Thermal Insulation, Experimental Study

Introduction

Since global climate change and the energy crisis become current focus, the energy consumption in residential housing is receiving increasing attention1. Among the major sources of energy consumption are heating and cooling systems in residential housing2. As a results, the global warming effect is estimated to increase the Earth’ surface temperature up to 6.4 °C by the end of 21003. To reduce energy consumption and improve human comfort, improving the thermal insulation performance of buildings has become a key topic of research. In recent years, various policies have been introduced to encourage the use of energy-saving technologies in buildings, addressing the challenges of the energy crisis and climate change.

Among these energy-saving technologies, the thermal performance of materials has an important impact on the indoor thermal environment of houses. The insulation properties of materials directly impact the thermal comfort and energy consumption under different conditions. Thus, finding approach to improve the insulation performance of building materials, such as walls and windows, is critical to achieve energy-efficient houses and reducing energy consumptions.

To meet this demand, the objective of this paper is to design and develop an experimental platform that simulates a small house model. The platform will test the insulation effects of different wall and window materials to assess their potential for energy savings. Based on the experimental data, we will provide guidance to designers, helping them choose the suitable energy-efficient materials for various climatic conditions. This research not only provide guidance to the energy-efficient technologies but also provide a positive impact on the environment.

Literature review

The area of energy saving research has attracted increasing attention due to the global warming and climate change. A wide array of papers has focused on increasing energy efficiency, developing new materials and reducing the environmental impacts. This section reviews and highlights major trends and the research gaps identified in existing papers. Aste et al. studied the impact of the thermal inertia of external walls on the building energy performance4. The results shows that the wall system which has the highest energy performance has a proper combination of the dynamic thermal transmittance and the thermal admittance value. Zbynek and Marek analyzed the heat transfer in vertical cavities with numerical modeling. The cavities have small cross-sectional areas in hollow bricks. The results shows the natural upward convection disappears only for the very narrow and high cavities5. Lu studied the specific methods of HVAC design technology and analyzed the approach that HVAC design needs to use the perspective of green buildings6. The results also indicate that the building envelope parameters have a significant impact on the thermodynamic performance. Shen analyzed the energy saving performance of the system based on meteorological data simulated on DeST software platform. The results show that the integrated system can save 1198.85 kWh of energy, compared to the electric heating hot water mode7. Chi studied an energy saving model of building wall with PBECA calculation software. The results show that energy saving efficiency of changing the light-saving wall with nanomaterials fly ash can achieve 65% of the energy saving standard8.

Air velocity at wall surface can impact the energy transfer. The higher of the air velocity will result in higher heat transfer rate9. Usually, the outside wall surface air velocity can vary from 1 m/s to 10 m/s. When the air velocity is increased, the heat transfer rate across the building wall will also increase. Therefore, it will influence the wall thermal performance. Researcher has investigated the convective heat transfer coefficients at the wall surface based on computational fluid dynamics method10. Both the air velocity and the building orientation have been investigated. The results show the energy transfer coefficient largely depends on the wind velocity and the wind direction has notable effect for vertical walls and the roofs. The study also provided the external convective heat transfer coefficient function with the relation to wind velocity and the wind-to-surface angle. Wang et al have proposed a concept of exhaust air insulation (EAI)11. It is composed of a porous material layer, a cavity and an external structure. The study developed an unsteady state heat transfer model in order to predict the EAI wall temperature. It also carried out experimental study to validate the heat transfer model. Results show significant benefit of the EAI wall. It can reduce 84.7% and 67% heat pickup in cooling season compared to the brick wall and the external insulation wall, respectively.

Pressure is another parameter which researchers are interested in. Zhao et al developed a numerical model to predict the thermal conductivity of fibrous insulation at different temperatures and pressures12. With the developed apparatus, the conductivity was measured across a temperature range of 300-973K, and a pressure range of 10-2-105 Pa. The results show that the calculated values match with the experimental values within 14.7%. Because of the lower thermal conductivity compared to traditional materials, vacuum insulation panels (VIPs) can effectively isolate the thermal energy. However, one of its key issues for building application is to minimize the failure in service. Simmler et al investigated the aging mechanism and reported results for different temperatures and humidities induced deteriorations13. The internal pressure increases is also calculated based on a dynamic thermal model. Liu et al developed an inverse method to calculate the effective thermal conductivity of silica aerogel14. The conductivity showed nonlinear increasing trend with increasing pressure as well as temperature. Different group of researchers also performed experimental study on other specimens and the results show similar trend15‘16.

The aging of insulation material can impact the heat transfer process. Batard et al investigated the long-term thermal properties of VIPs17. The paper proposed a method to determine the long-term thermal performance of VIPs under different building thermal insulation applications. It also proposed severity criteria and performance indicators to estimate the thermal efficiency. Fantucci et al. evaluated thermal conductivity impact under different ageing stages18. A dynamic heat transfer simulation is also performed with the temperature dependent thermal conductivity.

Existing studies have predominantly relied on simulation analyses, or high-cost experimental setups, leaving a shortage of affordable approaches to evaluate the insulation performance. This gap forms the key motivation of the present research, which seeks to provide a more accessible framework for evaluating material behavior and its impact on energy saving performance. To address these limitations, the present study develops a low-cost, easily implemented test set up that enables convenient and systematic investigation of insulation materials. In this paper, we also introduce novel performance indicators—the time required to reach thermal steady state and the corresponding steady-state temperature—which, to the best of our knowledge, have not been employed in previous literatures. These innovations provide a new framework for evaluating and comparing the thermal insulation performance.

Methods

Experimental Setup

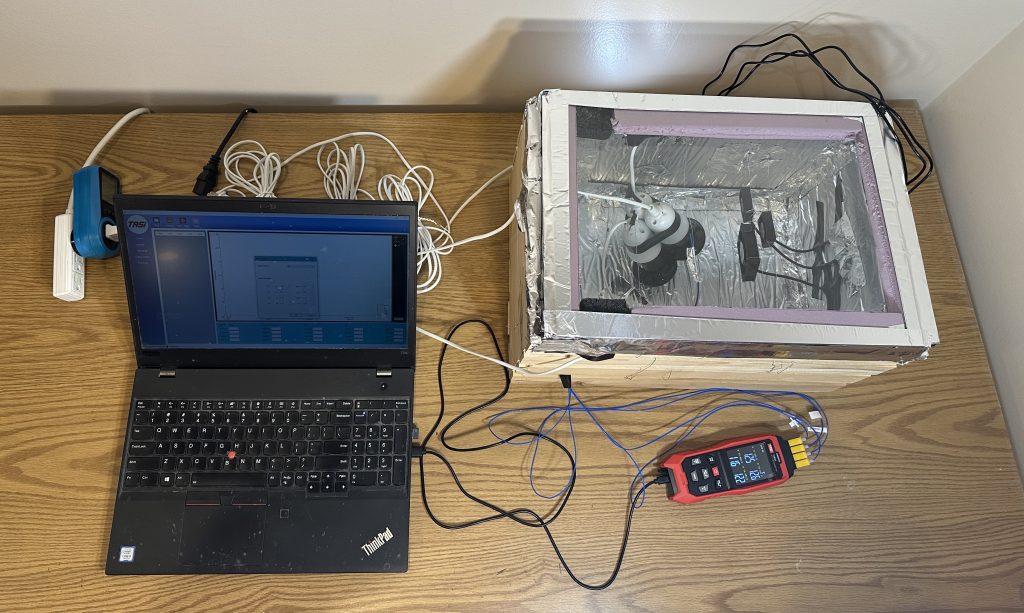

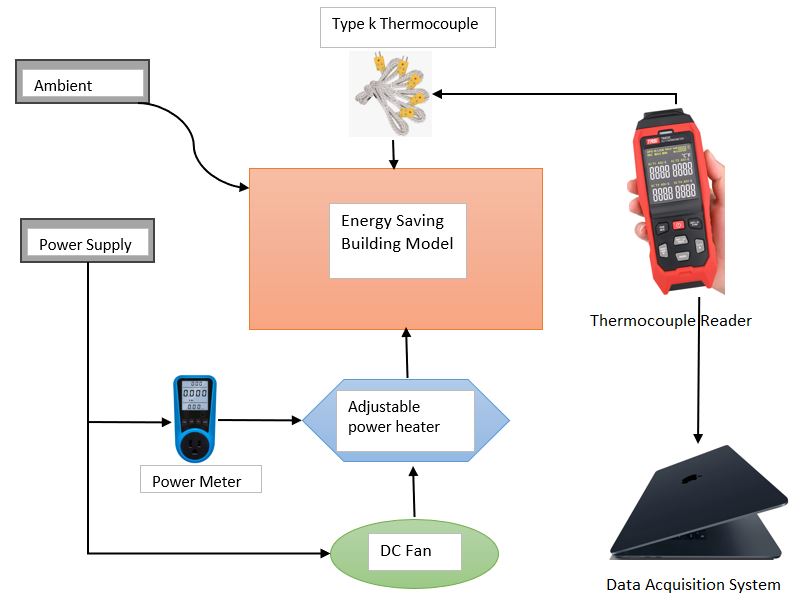

To better evaluate the thermal insulation performance of different materials, this paper design and build a small house model experimental platform to assess the insulation effects of different materials. The platform is designed not only to accurately simulate the thermal behavior of a house model but also have the flexibility to replace various types of materials, allowing for comparative experiments on different materials. The platform consists of the house model, temperature control and measure subsystem, and a data acquisition system, as shown in fig. 1. The schematic diagram of the energy saving building model house can be found in fig. 2.

The house model is able to physically simulate the heat conduction characteristics of real houses. The experimental house model is designed in a cubic shape, with dimensions of 0.44m in length, 0.30m in width, and 0.27m in height, in order to simulate the similar thermal environment of a single house. This size is large enough to reflect the thermal conduction effects of materials while also convenient for material replacement within the lab. The overall structure of the model, including the four walls and the base, is made of high-density insulation material to prevent any influence from the surrounding ambient on the experimental results. One wall, measuring 0.44m of length and 0.30m width, is designed for studying the impact of different materials.

Inside the house model, an adjustable-power heater (30W/60W) is used to manually control the internal temperature. Four K-type thermocouples (TC1, TC2, TC3 and TC4) are placed on the inside surface centers of four walls of the internal space to capture the overall temperature distribution in the house model. The TCs are around 2-4mm distance away from the wall and they measure the air temperatures. To ensure the adequate mixing, a small fan is used inside the box to circulate the air. The thermocouples are connected to a computer data acquisition system to record temperature data in real-time. The software used to record temperatures are TA612C digital thermocouple measuring tool.

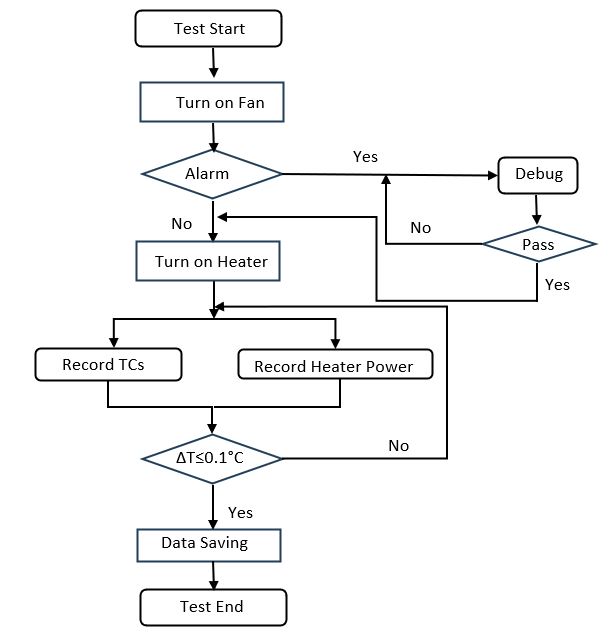

The system operating flowchart is designed as shown in fig.3. The experimental procedure starts with turning on the circulating fan. After confirming that the system operates without errors, the heater is turned on and the temperatures from the four thermocouples as well as the heater power are recorded simultaneously. The system is considered to have reached steady state when the average temperature measured by the four thermocouples varies by less than 0.1 °C. At this point, the test is regarded as complete.

Results

Results Analysis of the Transient State

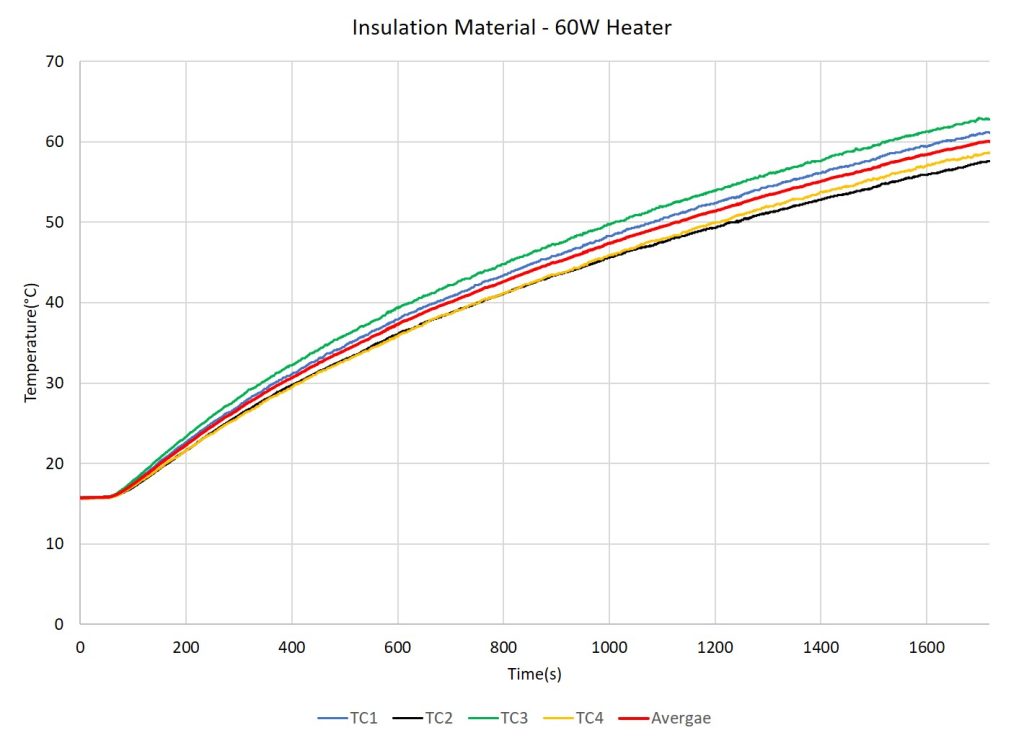

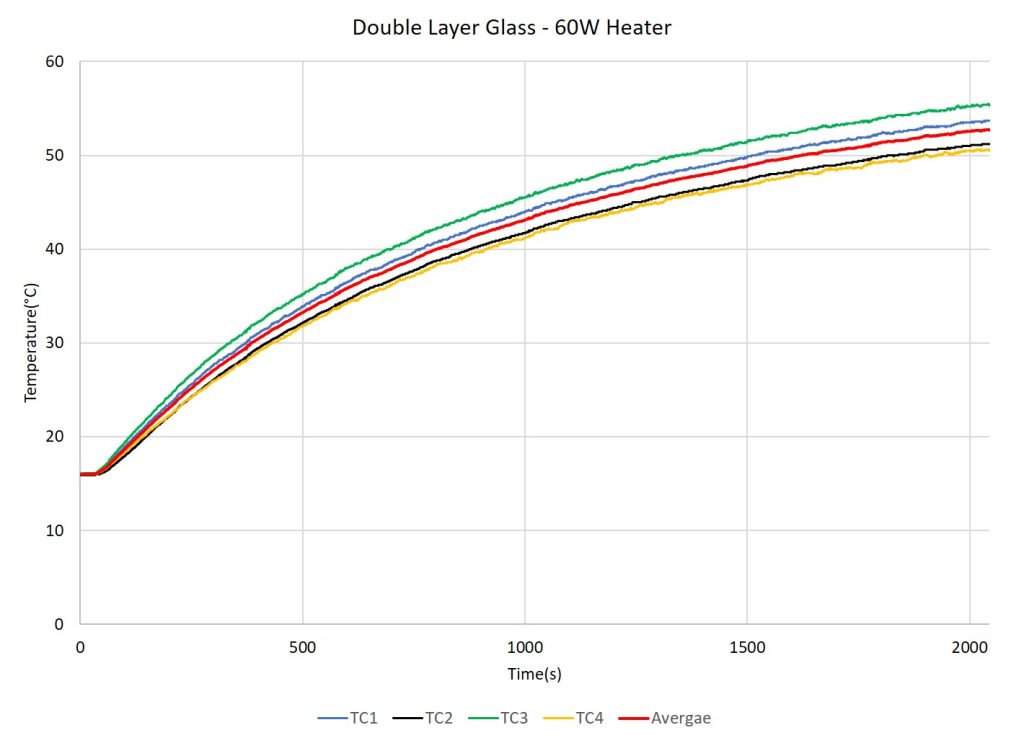

Two categories of testing were completed: with one heater (30W) and two heaters (60W). For each category, three materials are used: single glass, double glass, and insulation materials. The properties are listed in tab. 1. For each test, the initial temperature (and ambient temperature) of 16 °C has been selected as the system initial temperature. Once the test started, the 0 °C temperature will be applied on the outside of the test materials. The 0 °C temperature was achieved by the mixture of water and ice. The same initial temperature and boundary conditions ensure the consistence of current evaluation. Results analysis of the transient state were shown from fig. 4a to fig. 4f.

| Density (Kgm-3) | Thickness (mm) | Thermal Conductivity (Wm–1K–1) | |

| Single Layer Glass | 2760 | 2.4 | 0.8 |

| Double Layer Glass | – | 30.2 | – |

| Insulation Material | 28.8 | 25.4 | 0.005 |

Analysis of the Steady State

Fourier’s law of thermal conduction can be expressed as19:

Where

• q is the heat energy transferred within the time span

• k is the material’s conductivity

• A is the cross-sectional surface area

• ΔT is the temperature difference between the ends

• Δx is the distance between the ends

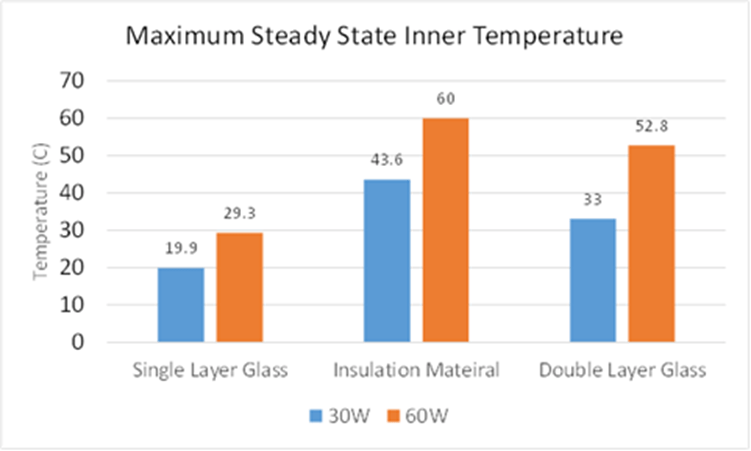

When the system achieves the steady state, the average of the inner temperatures, which include the TC1, TC2, TC3 and TC4, were shown in the Figures. With the single layer glass and the 30W heater, the steady state inner temperature is 19.9°C. The corresponding temperature increased to 33.0°C with double layer glass and 43.6°C with the insulation materials. The trends are similar with the 60W heater. It should be noted that when the inner temperature achieve 60°C, with the insulation materials, as shown in fig. 4e, the heater power is cut off considering the safety of the experiment. Fig. 5 presented the maximum steady state inner temperature for all cases. Results show, as expected, the 60W heater achieved higher steady state inner temperature than the 30W heater. For material wise, the single layer glass maintain the lowest temperature of 19.9°C while the insulation material can achieve 60°C inner temperatures.

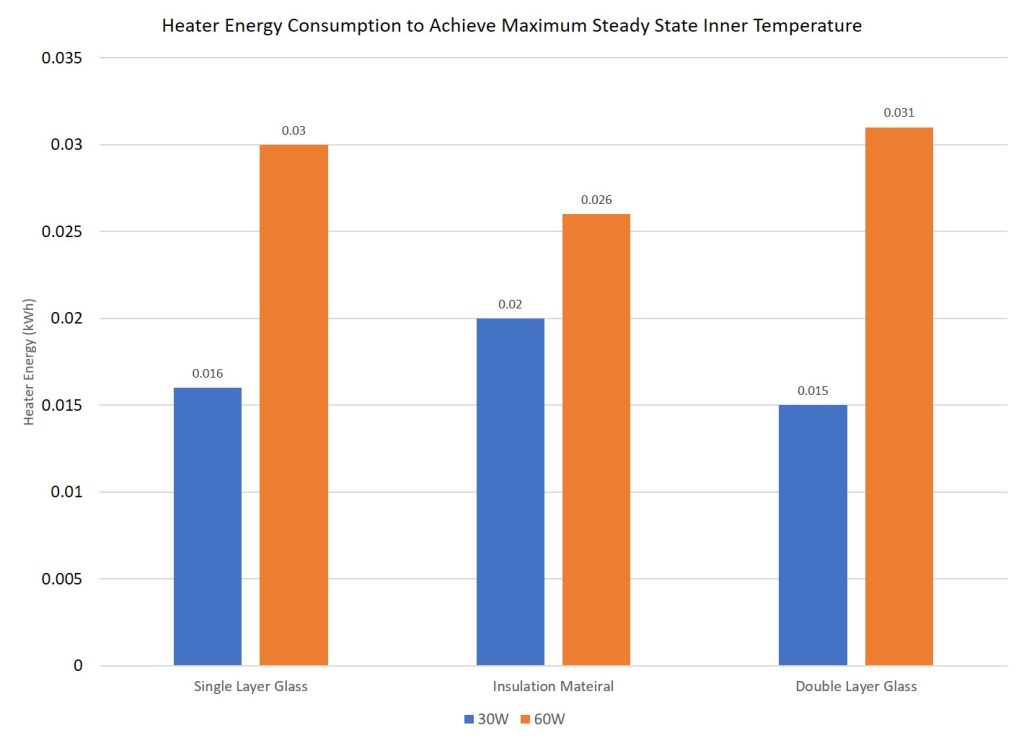

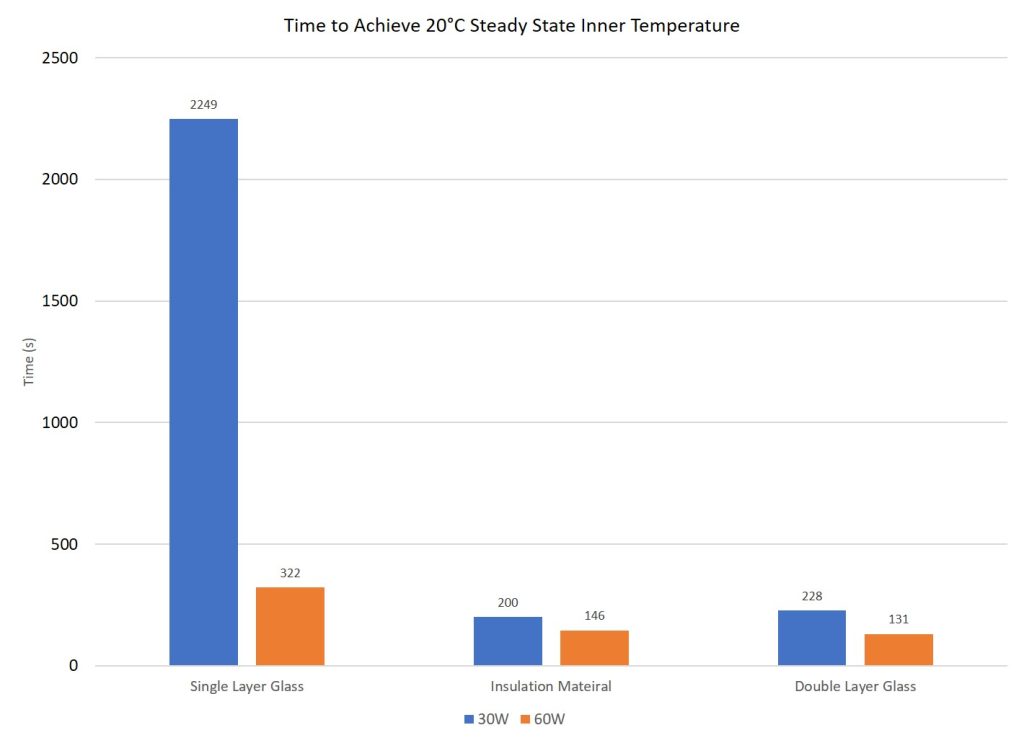

Fig. 6 displays the time required to achieve the steady state inner temperature. Fig.7 displays the heater energy consumption to achieve the steady state inner temperature. Since the steady state temperature are impacted by the materials and heater power, fig. 8 and fig. 9 show the time needed to achieve the 20 °C inner temperature and the corresponding heater energy consumption, respectively. As shown in charts, the single layer glass needs the longest time and the highest heater energy consumption to achieve the same temperature of 20°C, while the double layer glass and the insulation material demonstrated the similar behavior in regards to the heater energy consumption and the time needed to achieve 20°C inner temperatures.

Figure 8 | Time to Achieve 20°C Steady State Inner Temperature for Different Materials

Discussions

In this study, the steady state temperature and the time required to reach steady state were selected as the primary evaluation indices. The results show that, under the same 30 W heater power, the single layer glass configuration reached a steady state temperature of 19.9 °C, the double layer glass reached 33 °C, and the configuration with thermal insulation achieved 43.6 °C. The corresponding times to reach steady state were 2249 s, 1921 s, and 2546 s, respectively. Although the insulated configuration required a longer time (2546 s) to reach steady state than the other two materials, when both indicators are considered together, the thermal insulation exhibited the best overall performance. This also highlights that both metrics should be jointly assessed, with the steady state temperature being of greater importance. Furthermore, the heater power consumption was also measured. Under the same 30 W heater power, the energy required to reach steady state was 0.016, 0.015, and 0.020 kWh for the single layer glass, double layer glass, and insulation material configurations, respectively. Although the insulated configuration consumed the highest energy (0.020 kWh), it maintained a higher steady state temperature of 43.6 °C compared to the other two configurations, which reasonably explains the higher energy requirement

Conclusions

This study focuses on the systematic design and experimental research of a test platform for evaluating energy-efficient insulation materials in house. A lab scale experimental platform on house energy consumption is established. The platform can be used for further study on the house energy efficiency projects. This research also evaluated the thermal insulation performance of different wall and window materials. Both steady and transient behavior were studied on different materials. Under identical experimental conditions, insulation material exhibited a maximum steady-state temperature of 43.6 °C, whereas single layer glass maintained a markedly lower temperature of 19.9 °C and double layer glass stabilized at 33.0 °C, enabling a direct comparison among the three materials. Based on both evaluation indices, the steady state temperature and the time required to reach steady state, the single layer glass has the worst insulation performance while the insulation material demonstrate the advantages from the energy saving standpoint. This research not only contributes to the knowledge of energy consumption of a model house from thermal science perspective, but also lays a foundation for the future research aimed to improving efficiency and reduce energy consumption to select the energy-efficient building materials.

Future Research Directions

Although this study has designed and established a test platform and achieved above results, there is still different options for further extensive research. Future research can consider the following directions:

1. Evaluation Under Different Climate Conditions: Future studies may evaluate the performance of materials under different climate conditions to assess their effectiveness. This can provide more useful guidance for building design in different regions.

2. Evaluation of Material Combinations: In-depth study on the combination of different wall and window materials could provide the optimal combination for thermal insulation performance and cost-effectiveness, providing more flexible choices for building design.

References

- U. .S. Energy Information Administration. International Energy Outlook 2018. https://www.eia.gov/pressroom/presentations/capuano_07242018.pdf (2018). [↩]

- Z.Fang, N.Li, B.Li, G.Luo, Y.Huang. The effect of building envelope insulation on cooling energy consumption in summer, Energy and Buildings, 77,197-205 (2014). [↩]

- R.Pachauri, A.Reisinger, Climate Change 2007 Synthesis Report, IPCC, Switzerland (2007). [↩]

- N.Aste, A. Angelotti, and M. Buzzetti. The influence of the external walls thermal inertia on the energy performance of well insulated buildings, Energy and Buildings, 41,1181-1187 (2009). [↩]

- S.Zbynek, and K. Marek. Numerical simulation of heat transfer through hollow bricks in the vertical direction, Journal of Building Physics, 34, 325-350 (2010). [↩]

- X.Lu. Thermodynamic model of HVAC under building exterior wall. Thermal Science, 27, 983-990 (2023). [↩]

- X.Shen. Energy saving system for building cooling and heating integration based on building information modelling technology. Thermal Science, 28,1413-1421 (2024). [↩]

- M. Chi, K. Yu, C. Zhang, Y. Gao, and J. Lu. Building exterior wall thermal energy saving model based on green energy-saving nanomaterials, Thermal Science, 27, 1015-1022 (2023). [↩]

- N.Balaji, M.Mani, B. Venkatarama, Thermal performance of the building walls. Proceedings of BSA Conference 2013: 1st Conference of IBPSA-Italy. 151-160 (2013). [↩]

- M.Emmel, M.Abadie, N.Mendes, New external convective heat transfer coefficient correlations for isolated low-rise buildings. Energy and Buildings, 39,335-342 (2007). [↩]

- J.Wang, Q.Du, C.Zhang, X.Xu, W.Gang. Mechanism and preliminary performance analysis of exhaust air insulation for building envelope wall. Energy and Buildings, 173,516-529 (2018). [↩]

- S.Zhao, B.Zhang, X.He. Temperature and pressure dependent effective thermal conductivity of fibrous insulation. International Journal of Thermal Sciences, 48,440-448 (2009). [↩]

- H.Simmler, S.Brunner. Vacuum insulation panels for building application Basic properties, aging mechanisms and service life. Energy and Buildings, 37,1122-1131 (2005). [↩]

- H.Liu, X.Xia, Q.Ai, X.Xie,C.Sun. Experimental investigations on temperature-dependent effective thermal conductivity of nanoporous silica aerogel composite. Experimental Thermal and Fluid Science, 84,67-77 (2017). [↩]

- G.Wei,Y.Liu,X.Zhang,F.Yu,X.Du. Thermal conductivities study on silica aerogel and its composite insulation materials. International Journal of Heat and Mass Transfer, 54,2355-2366 (2011). [↩]

- Q.Tang,J.He,W.Zhang. Influencing factors of thermal contact conductance between TC4/30CrMnSi interfaces. International Journal of Heat and Mass Transfer, 86,694-698 (2015). [↩]

- A.Batard,T.Duforestel,L.Flandin,B.Yrieix. Prediction method of the long-term thermal performance of Vacuum Insulation Panels installed in building thermal insulation applications. Energy and Buildings, 178,1-10 (2018). [↩]

- S.Fantucci, A.Lorenzati, A.Capozzoli, M.Perino. Analysis of the temperature dependence of the thermal conductivity in Vacuum Insulation Panels. Energy and Buildings, 183,64-74 (2019). [↩]

- F.P.Incropera, D.P.DeWitt. Fundamentals of Heat and Mass Transfer. 6th ed., John Wiley & Sons, 2006. [↩]