Abstract

Selecting the appropriate propulsion system for a space mission, especially if a mission requires hybrid propulsion, is a complex process that requires extensive research and testing. The first step of this process is determining which propulsion system to focus and develop on. Usually, this is done by using holistic assessments of possible options. However, as the number of options and comparison parameters increases, inconsistency caused by humans can happen. Such complexity is further complicated if the mission requires a hybrid propulsion system between chemical and electric propulsion systems. This paper presents a heuristic method to derive a comprehensive and quantitative measure to compare propulsion systems against each other. The method is also tested on a dataset of hybrid systems with reference to the design of the Mercury Transfer Module (MTM) of the BepiColombo spacecraft and proves to be a proficient aid in preliminary research of developing hybrid systems with respect to mission requirements.

1. Introduction

Chemical-electric hybrid propulsion systems are propulsion systems that utilize separate chemical and electric systems simultaneously without sharing propellant, as opposed to multimode propulsion systems, which share propellant. Chemical-electric hybrid propulsion systems allow for multiple maneuvering tasks with maximum efficiency with their benefits proven through both theory and successful space launches1. Furthermore, there is a diverse array of chemical-electric systems for missions to choose from, which allow this type of propulsion system to cater to a diverse array of requirements. However, chemical-electric systems’ diversity comes with the predicament of selecting the most ideal combination. Developing the most optimal chemical-electric system requires “careful pairing” of electric and chemical thrusters; and there is a lack of literature on this subject because the important concept of ‘mission flexibility’ is difficult to quantify1. These two reasons make it almost impossible to create a perfect quantitative framework to evaluate these chemical-electric systems with each other.

Researchers currently use a holistic evaluation where they consider mission objectives, system constraints, and performance characteristics in a way that no factor dominates the other2. Even though such an approach provides a comprehensive comparison between different options, there is a chance that the researcher overlooks certain possibilities, especially as the number of comparison parameters and available options increases. Therefore, eventually, a mathematical method for evaluating these different systems will be needed, as computers can then automate these preliminary evaluations of the propulsion systems.

This paper will introduce a method that can use preexisting data to heuristically evaluate these systems. Research teams can utilize this placement to decide which combinations and technology to focus further research on, optimizing the research process. It will discuss the assumptions for the method to work and the mathematical model behind it. In essence, given a set of data, the method will return a score for each propulsion system based on how the specifications of each propulsion system fare with others with respect to the mission requirements. Additionally, the paper will use the method to evaluate the chemical-electric hybrid propulsion systems with reference to the mission requirement of the Bepicolombo Mercury Transfer Module (MTM), a hybrid propulsion system that needed to provide acceleration and braking in tandem with altitude control activities during cruise3.

2. Methodology

2.1 The coefficient of Mission Compatibility

2.1.1 System Combinations

Before comparing and ranking possible chemical-electric combinations with the system on the Bepicolombo, it is essential to first define what these systems are. For each chemical-electric system, an electric system will be taken from a dataset of electric systems, and a chemical system taken from the dataset of chemical systems. In essence, these systems in the context of the method are datasets created from combining information from existing datasets of chemical and electric propulsion systems.

2.1.2 The general equation

(1) ![]()

Equation 1 describes the equation to calculate ![]() , the coefficient of mission compatibility. This constant describes how suitable a chemical-electric combination is for a mission relative to other possible combinations in the dataset. A higher

, the coefficient of mission compatibility. This constant describes how suitable a chemical-electric combination is for a mission relative to other possible combinations in the dataset. A higher ![]() value denotes that a combination is more suitable. It is evaluated by adding the product between the relative value of a specification,

value denotes that a combination is more suitable. It is evaluated by adding the product between the relative value of a specification, ![]() , by the specification’s importance,

, by the specification’s importance, ![]() , for each and every specification. The sum is then divided by the sum of

, for each and every specification. The sum is then divided by the sum of ![]() .

. ![]() is, in other words, the weighted average of values with respect to the mission.

is, in other words, the weighted average of values with respect to the mission.

To compare every possible chemical-electric combination with each other, the ![]() value needs to be calculated for each and every system. Calculating this value manually is rather tedious and impractical, leading to the creation of an example code to automate this process. The full code with explanation can be viewed in the author’s repository, with only relevant code fragments being included and explained directly in the paper.

value needs to be calculated for each and every system. Calculating this value manually is rather tedious and impractical, leading to the creation of an example code to automate this process. The full code with explanation can be viewed in the author’s repository, with only relevant code fragments being included and explained directly in the paper.

In the equation, the ![]() parameter can be adjusted by the user based on the mission requirements for each and every variable. The guidelines for selecting an appropriate importance will be discussed later in this paper. In the example code, the importance data for variables can be stored in a dictionary as demonstrated in the code below:

parameter can be adjusted by the user based on the mission requirements for each and every variable. The guidelines for selecting an appropriate importance will be discussed later in this paper. In the example code, the importance data for variables can be stored in a dictionary as demonstrated in the code below:

The relative value of a specification, ![]() , can be found by using equation 2.

, can be found by using equation 2.

(2) ![]()

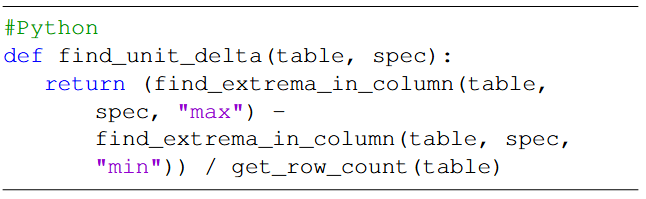

The equation can be implemented into the code as follows:

Where ![]() is the difference between the lowest value of the specification in the respective chemical or electric category and the value of the specification being used. For instance, if for a combination, the specification from the electric system is more preferable, then

is the difference between the lowest value of the specification in the respective chemical or electric category and the value of the specification being used. For instance, if for a combination, the specification from the electric system is more preferable, then ![]() will be calculated from taking the lowest value for such specification,

will be calculated from taking the lowest value for such specification, ![]() in the electric system’s dataset and minus it from the specification’s value for the electric system that is being used,

in the electric system’s dataset and minus it from the specification’s value for the electric system that is being used, ![]() . This results in equation 3.

. This results in equation 3.

(3) ![]()

In the code block below, ![]() is calculated with the following function, with function parameters being identical to the

is calculated with the following function, with function parameters being identical to the ![]() function. The

function. The ![]() with the argument

with the argument ![]() returns the smallest value in a column,

returns the smallest value in a column, ![]() .

.

The unit ![]() is calculated with equation 4.

is calculated with equation 4.

(4) ![]()

In the code below, ![]() identifies the type of propulsion and spec identifies the specification that unit

identifies the type of propulsion and spec identifies the specification that unit![]() is being calculated for.

is being calculated for.

The unit![]() serves as a relative and also ubiquitous unit for performance across specifications. It divides the difference between the highest value in a dataset and the lowest of the value in a data set into as many sections as the set’s number of objects,

serves as a relative and also ubiquitous unit for performance across specifications. It divides the difference between the highest value in a dataset and the lowest of the value in a data set into as many sections as the set’s number of objects, ![]() , each being 1

, each being 1 ![]() . As the method attempts to find the weighted average of the performance of these specifications for a chemical-electric system, it is necessary for every term of the summation to have the same unit. However, as each specification usually has a different unit of measure, such as seconds or Newtons, there has to be a unit that still reflects the difference between each propulsion system while also being ubiquitous. The unit

. As the method attempts to find the weighted average of the performance of these specifications for a chemical-electric system, it is necessary for every term of the summation to have the same unit. However, as each specification usually has a different unit of measure, such as seconds or Newtons, there has to be a unit that still reflects the difference between each propulsion system while also being ubiquitous. The unit![]() is sufficient as a scale to compare the different propulsion systems together, as the unit is consistent and not changing. Furthermore, regardless of specification, there are always

is sufficient as a scale to compare the different propulsion systems together, as the unit is consistent and not changing. Furthermore, regardless of specification, there are always ![]() unit

unit![]() between the best and worst propulsion system in that dataset, making it suitable as a ubiquitous unit for every specifications. This allows different variables that initially had different units to be added together for the weighted average. Lastly, the step of dividing

between the best and worst propulsion system in that dataset, making it suitable as a ubiquitous unit for every specifications. This allows different variables that initially had different units to be added together for the weighted average. Lastly, the step of dividing ![]() \textbf{d} by unit

\textbf{d} by unit![]() to calculate

to calculate ![]() reflects how better a system’s specification is from the worst in the dataset in units of unit

reflects how better a system’s specification is from the worst in the dataset in units of unit![]() .

.

For a purely comparative purpose, the final step of dividing by the total sum of ![]() can be omitted. Nevertheless, for analytical purposes, this step provides a more precise and refined reflection of how these systems fare with each other. It provides the average number of unit

can be omitted. Nevertheless, for analytical purposes, this step provides a more precise and refined reflection of how these systems fare with each other. It provides the average number of unit![]() a chemical-electric system has, and by the way unit

a chemical-electric system has, and by the way unit![]() is calculated, it quantifies how much better the system performs relatively to the poorest performing system. In essence, dividing by the total sum of

is calculated, it quantifies how much better the system performs relatively to the poorest performing system. In essence, dividing by the total sum of ![]() is not necessary for purely comparison, but provides a more reflective measure of a system’s compatibility with a mission.

is not necessary for purely comparison, but provides a more reflective measure of a system’s compatibility with a mission.

2.2 Possible Parameters

With the general formula defined, the next step is to determine which parameters to be considered for evaluation. These parameters can be categorized into mission parameters and system parameters, of which only system parameters are considered in the general equation, as the equation’s aim is to evaluate the propulsion system. Mission parameters can be total velocity change or payload, or any additional factors that are independent of the type of propulsion while also pertaining to the mission; while system parameters are parameters related to the specific propulsion systems being used. The two types of system parameters are mission-independent system parameters (MISP) and mission-dependent system parameters (MDSP).

To evaluate hybrid propulsion systems for flexible missions, we would mainly want to use MISP, as they describe each system independently in accordance with flexible missions. Examples of MISP include Total Impulse, Specific Impulse, Input Power, Thrust to Power ratio, Specific Mass, Loaded Weight, Average Thrust4.. The ![]() values of MISP can be taken directly from the dataset, with only the importance being affected by the mission.

values of MISP can be taken directly from the dataset, with only the importance being affected by the mission.

Meanwhile, the MDSP’s an values are evaluated from functions that include both the data set and mission parameters. Example of MDSP are combined specific impulse, propulsion system mass, thrust time, and transportation rate, which can be calculated using mathematical formulae1. This also highlights the role of mission parameters, while not directly included in the equation, are determinants of included parameters’ importance and the value of MDSPs. As MDSP takes into consideration the interdependency between the chemical and electric system, they are suitable to use for defined missions. Additionally, even though the method treats each propulsion system as an independent system, the spacecraft that each system is propelling includes both systems, which leads to some parameters being dependent on the two types of propulsions used in addition to the mission-parameters. An example is the MDSP “propulsion system mass estimation”, which is also covered in the paper by Berg & Rovey1.

In essence, system-parameters are to be inputted as the an values in the equation, with some being dependent on mission-parameters, and missions-parameters are to be used to evaluate these dependent mission-parameters in addition to determining the ![]() of the parameters. Listed in this section was a list of possible parameter that can be used. Ultimately, as mission requirements varies and aerospace technology gradually changes and become different, it is up to the user to identify which parameter are important to their mission and used in evaluation.

of the parameters. Listed in this section was a list of possible parameter that can be used. Ultimately, as mission requirements varies and aerospace technology gradually changes and become different, it is up to the user to identify which parameter are important to their mission and used in evaluation.

2.3 Determining Importance

As elaborated above, each parameter has an assigned importance, ![]() , for them. Because different missions have different objectives, such as some valuing payload mass more than distance traveled. Hence, it is up to the user’s discretion to determine the importance of each parameter. Nevertheless, there are guidelines in determining parameter importance. We will take the example of a CubeSat satellite’s parameters5 for reference. Firstly, parameters that are considered crucial in a mission, such as transfer time, lifetime, and propellant mass for a CubeSat satellite, should have an importance that is greatly higher than other parameters. The goal is to make the importance great enough that there should be distinct groups forming amongst the propulsion systems in which the lower ranking group will be immediately removed, this ideal importance can be determined through trial and error, a process that can be automated. Secondly, other parameters that are not as important, but still has impact, such as Specific Impulse and Power Consumption, should have lower importance than the main parameters, but can have discrepancy in importance with each other, as long as it is not as overwhelming as the difference between these parameters and the main parameters

, for them. Because different missions have different objectives, such as some valuing payload mass more than distance traveled. Hence, it is up to the user’s discretion to determine the importance of each parameter. Nevertheless, there are guidelines in determining parameter importance. We will take the example of a CubeSat satellite’s parameters5 for reference. Firstly, parameters that are considered crucial in a mission, such as transfer time, lifetime, and propellant mass for a CubeSat satellite, should have an importance that is greatly higher than other parameters. The goal is to make the importance great enough that there should be distinct groups forming amongst the propulsion systems in which the lower ranking group will be immediately removed, this ideal importance can be determined through trial and error, a process that can be automated. Secondly, other parameters that are not as important, but still has impact, such as Specific Impulse and Power Consumption, should have lower importance than the main parameters, but can have discrepancy in importance with each other, as long as it is not as overwhelming as the difference between these parameters and the main parameters

2.4 Flexible Mission & Defined Missions

This method will work for flexible mission, mission or parts of a mission that does not require a strict trajectory, as the chemical and electric systems are independent of each other in these missions; whereas in defined mission, the electric system is highly dependent on the type of chemical maneuver performed6. As the two systems are now independent, it allows the method to directly use data retrieved about the specifications of each chemical and electric propulsion system in comparisons, because these specifications will now then not be affected by how the chemical and propulsion systems are paired together.

For the method to work for defined mission, additional MDSP related to the mission needs to be added. These can include the system total mass estimation or sizing of the chemical thruster1. Moreover, the dataset for each individual propulsion system needs to be modified with respect to how the chemical and electric systems are planned to be integrated with each other. As this paper’s purpose is to introduce the method, it will focus on flexible mission, and the specific calculations for extra MDSP pertaining to defined missions are outside the scope of this paper.

2.5 Testing Methodology

The BepiColombo MTM is a module a that needed to provide acceleration and braking in tandem with altitude control activities during cruise. It is a system that was extensively researched and developed by the European Space Agency3. This paper will use the method to evaluate and compare an array of possible hybrid propulsion and see which one would be the most compatible with the BepiColombo MTM’s mission. It will then compare the results with the actual propulsion system the BepiColombo MTM used. This result will be used to evaluate both the accuracy and precision of the method.

This process will have four steps. The first step is to generate possible hybrid systems using a dataset of electric and chemical propulsion. The second step is to determine a number of sets of different variables and variable importance using design reports on the BepiColombo MTM, these three sets are to reflect possible variations in deduction from reports, attempting to reflect the precision of the method. The third step is to apply the method to possible systems and obtain the ranking. The final step is to evaluate the results of different sets of hybrid propulsion system with reference to the system actually utilized on the BepiColombo MTM.

3. Testing and Results

3.1 Determining Importance

3.1.1 Electric System

The first step in determining importance for variables is to determine the variables with high weights, as these heavily affect the ranking. For the electric system of the Bepicolombo, two major requirements directly pertain to the propulsion system itself, which are: The electric system must be capable of being throttled over a thrust range between ![]() and

and ![]() , and the total impulse shall be

, and the total impulse shall be ![]() 7.. From these two requirements, it can be inferred that the electric propulsion for this system needs to have a high specific impulse to facilitate a high total impulse while also using fuel efficiently (as mass is a major concern for low thrust propulsion systems). On the other hand, another important parameter for the electric system was the thrust-to-mass ratio8. Even though this specification is not included in the data table, its value can be calculated from taking the inverse of the system’s specific mass, which was originally in kg/kW. However, the thrust-to-mass ratio is not as important as specific impulse to the mission, as the total impulse is relatively high for electric propulsion systems, which raises the concern of fuel mass, which outweighs the electric propulsion system’s weight. With a reason similar to thrust-to-mass ratio, the thrust-to-mass ratio is the thrust-to-power power ratio (a higher ratio means a lighter power generation system)9. One additional factor that would be beneficial in designing would be the input power of the propulsion system; a higher value would reduce the number of thruster units needed, thereby reducing system complexity.

7.. From these two requirements, it can be inferred that the electric propulsion for this system needs to have a high specific impulse to facilitate a high total impulse while also using fuel efficiently (as mass is a major concern for low thrust propulsion systems). On the other hand, another important parameter for the electric system was the thrust-to-mass ratio8. Even though this specification is not included in the data table, its value can be calculated from taking the inverse of the system’s specific mass, which was originally in kg/kW. However, the thrust-to-mass ratio is not as important as specific impulse to the mission, as the total impulse is relatively high for electric propulsion systems, which raises the concern of fuel mass, which outweighs the electric propulsion system’s weight. With a reason similar to thrust-to-mass ratio, the thrust-to-mass ratio is the thrust-to-power power ratio (a higher ratio means a lighter power generation system)9. One additional factor that would be beneficial in designing would be the input power of the propulsion system; a higher value would reduce the number of thruster units needed, thereby reducing system complexity.

In essence, there are four main variables to consider for the electric propulsion systems:

In essence, there are four main variables to consider for the electric propulsion system:

- High Weight: Specific-impulse

- Moderate Weight: thrust-to-mass ratio, thrust-to-power ratio

- Minimum Weight: Input power

Therefore arriving at the three possible sets of variable and importance in Table 1. These three sets are to test the consistency of the method.

| Variable/ Set | eA | eB | eC |

| Specific-impulse | 35 | 40 | 60 |

| Thrust-to-mass ratio | 20 | 20 | 20 |

| Thrust-to-power ratio | 20 | 20 | 20 |

| Input power | 1 | 1 | 1 |

3.1.2 Chemical System

To see the main variables for the chemical system, we have to consider its purpose and relationship with other parts of the system. Firstly, chemical thrusters on the MTM were used to perform precise orbit determination and trajectory correction when necessary8. This means that they do not need a high thrust value, meaning that thrust is a variable of low importance. Moreover, this means that though necessary, the uptime for the chemical propulsion is low, decreasing concern about fuel usage. Secondly, the two most important objectives for the chemical propulsion system is having a high specific-impulse and being mass efficient10. Even though the paper discusses the MPO propulsion system, independent of the MTM, the same principle applies since the MTM is included as a payload of the MPO. Combining these two ideas, specific impulse and thrust-to-weight ratio are important variables, but they are not as important as engine mass.

In essence, there are four main variables to consider for the chemical propulsion systems:

- High Weight: Engine Mass

- Moderate Weight: Specific Impulse, Thrust to Weight

- Minimum Weight: Max Thrust

Therefore arriving at the three possible sets of variable and importance in Table 2. The values for the importance of chemical propulsion variables are considerably smaller than that of the electric propulsion system because the electric propulsion system is the main mode of propulsion for the MTM.

To see the main variables for the chemical system, we have to consider its purpose and relationship with other parts of the system. Firstly, chemical thrusters on the MTM were used to perform precise orbit determination and trajectory correction when necessary8. This means that they do not need a high thrust value, meaning that thrust is a variable of low importance. Moreover, this means that though necessary, the uptime for the chemical propulsion is low, decreasing concern about fuel usage. Secondly, the two most important objectives for the chemical propulsion system is having a high specific-impulse and being mass efficient10.. Even though the paper discusses the MPO propulsion system, independent of the MTM, the same principle applies since the MTM is included as a payload of the MPO. Combining these two ideas, specific impulse and thrust-to-weight ratio are important variables, but they are not as important as engine mass.

In essence, there are four main variables to consider for the chemical propulsion systems:

- High Weight: Engine Mass

- Moderate Weight: Specific Impulse, Thrust to Weight

- Minimum Weight: Max Thrust

Therefore arriving at the three possible sets of variable and importance in Table 2. The values for the importance of chemical propulsion variables are considerably smaller than that of the electric propulsion system because the electric propulsion system is the main mode of propulsion for the MTM.

| Variable/ Set | cA | cB | cC |

| Thrust | 1 | 1 | 1 |

| Specific-impulse | 2 | 1.5 | 4 |

| Engine Mass | 4 | 5 | 8 |

| Thrust-to-weight | 2 | 1.5 | 4 |

3.2 Reference Dataset

The dataset being referenced in this paper will be taken from the book “Space Mission Analysis and Design” by Wiley J. Larson and James R. Wertz. This data set includes 6 types of electric propulsion with 17 distinct systems. As this method is interested in the different types of propulsions and is only a heuristic method, it is appropriate to find the average value amongst the systems using the same type of propulsion. For chemical propulsion, the data from the table “Flight-Qualified Thrusters Used to Control Spacecraft Attitude and Velocity.” will be used. Some value exists in a range, so the median value would be used instead. Even though some chemical systems in the dataset share the same type of propellant and theory, all of their variables: thrust, engine mass, specific, and thrust differ greatly. Thus, finding the average value for each variable is not appropriate in this case. Therefore, the chemical systems, even with the same propellant, are treated as separate variables. Furthermore, among these variables, thrust to weight ratio has the greatest discrepancy between systems, making it a suitable identifier for the system alongside the propellant type. With this information, the tables in Appendix A can be generated.

3.3 Results

By combining the importance sets for chemical and electric propulsion, we arrive at nine different result tables from nine different combinations between the importance data sets. Below are the top five combinations with the highest A value for each combination.

| System ID | a_value | electric_type | chemical_type |

| 4 | 4.018891377 | Resistojet | N2H4 – 31.79 |

| 3 | 4.003707738 | Resistojet | N2H4 – 15.86 |

| 1 | 3.849643079 | Resistojet | N2H4 – 1.03 |

| 13 | 3.760168536 | Resistojet | N2H4 – 329.15 |

| 119 | 3.748744709 | Ion Thruster | N2H4 – 31.79 |

| System ID | a_value | electric_type | chemical_type |

| 4 | 4.265338966 | Resistojet | N2H4 – 31.79 |

| 3 | 4.253895341 | Resistojet | N2H4 – 15.86 |

| 1 | 4.101764059 | Resistojet | N2H4 – 1.03 |

| 119 | 3.995192298 | Ion Thruster | N2H4 – 31.79 |

| 118 | 3.983748673 | Ion Thruster | N2H4 – 15.86 |

| System ID | a_value | electric_type | chemical_type |

| 4 | 4.75068373 | Resistojet | N2H4 – 31.79 |

| 3 | 4.723133039 | Resistojet | N2H4 – 15.86 |

| 119 | 4.503775485 | Ion Thruster | N2H4 – 31.79 |

| 118 | 4.476224794 | Ion Thruster | N2H4 – 15.86 |

| 1 | 4.441698697 | Resistojet | N2H4 – 1.03 |

| System ID | ad_value | electric_type | chemical_type |

| 119 | 3.873814448 | Ion Thruster | N2H4 – 31.79 |

| 118 | 3.859474344 | Ion Thruster | N2H4 – 15.86 |

| 4 | 3.795619634 | Resistojet | N2H4 – 31.79 |

| 3 | 3.78127953 | Resistojet | N2H4 – 15.86 |

| 116 | 3.713968833 | Ion Thruster | N2H4 – 1.03 |

| System ID | a_value | electric_type | chemical_type |

| 119 | 4.106570504 | Ion Thruster | N2H4 – 31.79 |

| 118 | 4.095762636 | Ion Thruster | N2H4 – 15.86 |

| 4 | 4.02837569 | Resistojet | N2H4 – 31.79 |

| 3 | 4.017567822 | Resistojet | N2H4 – 15.86 |

| 116 | 3.952083092 | Ion Thruster | N2H4 – 1.03 |

| System ID | a_value | electric_type | chemical_type |

| 119 | 4.58011347 | Ion Thruster | N2H4 – 31.79 |

| 118 | 4.553968427 | Ion Thruster | N2H4 – 15.86 |

| 4 | 4.508301907 | Resistojet | N2H4 – 31.79 |

| 3 | 4.482156864 | Resistojet | N2H4 – 15.86 |

| 116 | 4.286892981 | Ion Thruster | N2H4 – 1.03 |

| System ID | a_value | electric_type | chemical_type |

| 119 | 4.26039363 | Ion Thruster | N2H4 – 31.79 |

| 118 | 4.24866082 | Ion Thruster | N2H4 – 15.86 |

| 116 | 4.12961086 | Ion Thruster | N2H4 – 1.03 |

| 128 | 4.06047144 | Ion Thruster | N2H4 – 329.15 |

| 121 | 4.048885807 | Ion Thruster | N2H4 – 120.83 |

| System ID | a_value | electric_type | chemical_type |

| 119 | 4.450830412 | Ion Thruster | N2H4 – 31.79 |

| 118 | 4.441987611 | Ion Thruster | N2H4 – 15.86 |

| 116 | 4.324431621 | Ion Thruster | N2H4 – 1.03 |

| 121 | 4.116246775 | Ion Thruster | N2H4 – 120.83 |

| 120 | 4.054979903 | Ion Thruster | N2H4 – 64.58 |

| System ID | a_value | electric_type | chemical_type |

| 119 | 4.820772204 | Ion Thruster | N2H4 – 31.79 |

| 118 | 4.799058524 | Ion Thruster | N2H4 – 15.86 |

| 116 | 4.577250103 | Ion Thruster | N2H4 – 1.03 |

| 121 | 4.424662525 | Ion Thruster | N2H4 – 120.83 |

| 120 | 4.273985685 | Ion Thruster | N2H4 – 64.58 |

4. Discussion

4.1 Method’s Precision and Accuracy

On the aspect of method’s accuracy, the method proves to be sufficient. The MTM module utilizes Ion Thrusters11 which was the top ranking electric propulsion system for 7 of the 9 tables. Moreover, across every table, N2H4 – 31.79 was the chemical propulsion for the highest rated system; the second highest always being N2H4 – 15.86. Both of these chemical propulsion systems are similar to that actually used on the BepiColombo, which also used Hydrazine engines12. Furthermore, from the manufacturer’s website, these two engines had a similar thrust to weight ratio to the engines used on the MTM13.

The results from the tables consistently have system 119 and 118, the two systems most similar to the one deployed on the MTM, as the top ranking 2 systems, with only 3 tables disagreeing with this statement. This shows that importance assignment for variables can be relatively loose, but also shows that in certain cases, can change the results (such as table 1, 2, and 3 having different results than the rest). Nevertheless, these results show that, in the majority of cases where there is sufficient distinction between high importance and low importance variables, the heuristic method can provide consistent results.

If the method of taking the most commonly high-ranked system seems unrigorous, one can also find the mean A value for each combination mentioned in the tables. Once again, system 119 and 118 ranks first, with an average A across every table being 4.260 and 4.307 respectively; system 4 and 3 also being in the top 4. Therefore, it can be deducted that the method is sufficiently consistent and accurate.

As stated, a major benefit of utilizing the method to evaluate the combination is its ease of result visualization and interpretation. The A provides a combination’s average ranking above the lowest performing combination across variables. In this specific scenario, system 119 is on average 4.307 unit∆, and 119 is 4.260 unit∆ above the lowest ranking system. This is rather surprising since there were a total of 138 systems being ranked. Such a difference between the average place of the highest ranked and the total number of systems highlights the diversity and compromises these propulsion systems had to make (such as between specific-impulse and maximum thrust)

4.2 Implementation of the Method in Research

As previously mentioned, currently, the most prevalent method for selecting a propulsion system for a mission is through a holistic review of multiple factors of a propulsion system with respect to the mission’s requirements2.

The method introduced in this paper provides two improvements in performance upon the preexisting method. The first is that it automates the holistic process via the users assigning weights to parameters based on mission requirements. This is especially helpful to researchers as the number of available propulsion types and systems increases. The second benefit is that it maintains the holistic framework’s consistency. The method removes any of the researcher’s bias towards any propulsion systems by only allowing the researcher to decide the weight of each parameter, defining the comparison framework. Each propulsion system can then be consistently evaluated by the algorithm, ensuring that there is no unjustified preference of propulsion system.

Additionally, as the method is automated, it can quickly provide researchers with a comparison of the possible propulsion system instead of the researcher manually comparing the systems. Moreover, researchers can add any parameters that are necessary to fulfill the mission requirements, as long as a numerical value that quantifies that parameter can be added in the data about each propulsion system. This means that the method can be used for a wide variety of missions with varying mission requirements.

4.3 Method’s Limitations and Possible Compromise

However, as a heuristic method that heavily depends on user input, the method has its limitations. As seen in Table 1, 2, and 3, if weights assignment are not appropriate (such as the importance of a major variable being too close to a less important variable), the method can produce a result that does not truly reflect the mission’s requirements. Furthermore, deducting variable importance from mission requirements, if not done properly and subjectively, can result from a set of not-ideal results. Moreover, judgemental errors can always happen, and as this is a heuristic method that heavily depends on user input, a misinput due to a misinterpretation of the mission requirements would be detrimental to the results.

Another limitation to the method is how outliers are treated and how they affect results. An example is the specific-impulse variable for Ion Thrusters. The outlier caused the unit![]() for the parameter to be unexpectedly large, as the outlier is significantly larger than the rest of the dataset. A higher unit

for the parameter to be unexpectedly large, as the outlier is significantly larger than the rest of the dataset. A higher unit![]() causes the underevaluation of both the outlier and the rest of the dataset. On the other hand, this also undermines other electric system’s true performance. The outlier greatly increase the unit

causes the underevaluation of both the outlier and the rest of the dataset. On the other hand, this also undermines other electric system’s true performance. The outlier greatly increase the unit![]() , making other electric system’s performance measured in unit

, making other electric system’s performance measured in unit![]() lower than its original unit would reflect.

lower than its original unit would reflect.

The method can account for the outlier by deriving unit![]() using equation

using equation ![]() .

.

(5) ![]()

This formula uses the third quartile as

Another limitation to the method comes from its lack of research depth caused by some parameters pertaining to propulsion systems being difficult to quantify. An example of such parameter is subsystem integration, how well can the chemical and electric propulsion systems be implemented together. Nevertheless, as the method allows researchers to add additional parameters, attempts can be made to quantify these. This can be done through formula, such as the hybrid rocket equation1. These equations can be added by the researcher depending on the mission’s requirements to be computed by the computer and treated as another parameter for the method. Regardless, researchers should only use this method as a preliminary tool to decide which propulsion systems to further develop. Though the method provides researcher with a clear direction on which propulsion systems have priority for research, the actual success of propulsion systems can only be guaranteed through prototyping and further testings2.

5. Conclusion

Selecting the appropriate propulsion system for a space mission, especially if a mission requires hybrid propulsion, is a complex process that requires extensive research and testing. The first step of this process is determining which propulsion system to focus and develop on. Usually, this is done using holistic assessments of possible options. However, as the number of options and comparison parameters increases, inconsistency caused by humans can happen. This paper provided a method that makes this process consistent via consistent mathematical formula based on the comparison framework set by the user. Such a method not only maintains the consistency of the comparisons, but also allows automation by a computer.

Using the design process and mission requirements of the MTM module of the BepiColombo mission as an example, the method was applied to a dataset of possible propulsion systems combinations. The result shows that even though there were some limitations on user’s input and outliers in the data affecting the accuracy of the results, the method is sufficient for the preliminary evaluation of different hybrid chemical-electric propulsion systems.

Appendix A: Table for Reference Dataset

| Concept | Thrust | Engine Mass/ (1/kg) | Specific Impulse | Thrust-to-weight |

| N2H4 – 1.03 | 0.155 | 6.667 | 210 | 1.03 |

| N2H4 – 0.54 | 0.38 | 1.429 | 302.5 | 0.54 |

| N2H4 – 15.86 | 2.22 | 7.143 | 222.5 | 15.86 |

| N2H4 – 31.79 | 4.45 | 7.143 | 220 | 31.79 |

| N2H4 – 64.58 | 15.5 | 4.167 | 225 | 64.58 |

| N2H4 – 120.83 | 29 | 4.167 | 227.5 | 120.83 |

| N2H4 – 140 | 56 | 2.500 | 227.5 | 140 |

| N2H4 – 71.61 | 111 | 0.645 | 227.5 | 71.61 |

| N2H4 – 53.20 | 133 | 0.400 | 233.5 | 53.2 |

| N2H4 – 125 | 200 | 0.625 | 233 | 125 |

| N2H4 – 276.59 | 567 | 0.488 | 235 | 276.59 |

| N2H4 – 118.14 | 1335 | 0.088 | 235 | 118.14 |

| N2H4 – 329.15 | 2699 | 0.122 | 233 | 329.15 |

| N2O4/CH6N2 – 22.00 | 11 | 2.000 | 285 | 22 |

| N2O4/CH6N2 – 31.43 | 22 | 1.429 | 290 | 31.43 |

| N2O4/CH6N2 – 79.29 | 111 | 0.714 | 300 | 79.29 |

| N2O4/CH6N2 – 108.41 | 445 | 0.244 | 308 | 108.41 |

| N2O4/CH6N2 – 100 | 450 | 0.222 | 305 | 100 |

| N2O4/CH6N2 – 97.78 | 440 | 0.222 | 325 | 97.78 |

| N2O4/CH6N2 – 118.24 | 450 | 0.263 | 309 | 118.42 |

| N2O4/N2H4 – 98.89 | 445 | 0.222 | 322 | 98.89 |

| N2O4/N2H5 – 80.00 | 440 | 0.182 | 330 | 80 |

| N2O4/N2H6 – 112.50 | 450 | 0.250 | 317 | 112.5 |

| concept | Specific Impulse | Input Power | Thrust-to-power | Thrust-to-mass |

| Resistojet | 297.5 | 0.7 | 824 | 0.769 |

| Arcjet (NH3) | 480 | 0.85 | 135 | 0.329 |

| Arcjet (N2H4) | 541 | 1.985 | 125.5 | 0.286 |

| Pulsed Plasma Thruster (PPT) | 800 | 0.025 | 113 | 0.007 |

| Hall Effect Thruster (HET) | 1760 | 3 | 54.77 | 0.154 |

| Ion Thruster | 3084 | 0.988 | 33.9 | 0.048 |

References

- Berg, S., & Rovey, J. (2013). Assessment of High-Power Electric Multi-Mode Spacecraft Propulsion Concepts. https://eplab.ae.illinois.edu/Publications/IEPC-2013-308.pdf [↩] [↩] [↩] [↩] [↩] [↩]

- Parker, K., & Folta, D. (n.d.). Propulsion System. https://ntrs.nasa.gov/api/citations/20205003834/downloads/CSMH%20-%20III-8%20-%20Propulsion%20System_For%20Book-%20200701_final.docx.pdf [↩] [↩] [↩]

- Benkhoff, J., Murakami, G., Baumjohann, W., Besse, S., Bunce, E., Casale, M., Cremosese, G., Glassmeier, K.-H. ., Hayakawa, H., Heyner, D., Hiesinger, H., Huovelin, J., Hussmann, H., Iafolla, V., Iess, L., Kasaba, Y., Kobayashi, M., Milillo, A., Mitrofanov, I. G., & Montagnon, E. (2021). [↩] [↩]

- James Richard Wertz, & Larson, W. J. (1999). Space mission analysis and design. Dordrecht, The Netherlands. [↩]

- Mani, K. V., Cervone, A., & Topputo, F. (2019). Combined Chemical–Electric Propulsion for a Stand-Alone Mars CubeSat. Journal of Spacecraft and Rockets, 56(6), 1816–1830. https://doi.org/10.2514/1.a34519 [↩]

- Berg, S., & Rovey, J. (2013). Assessment of High-Power Electric Multi-Mode Spacecraft Propulsion Concepts. https://eplab.ae.illinois.edu/Publications/IEPC-2013-308.pdf [↩]

- Arcis, N., Bulit, A., Varinois, A., Ruault, J.-M., Gollor, M., Roggen, J., & Rul, K. (2015). D2. 2 Database of EPS key requirements and technical specifications for current and future missions. [↩]

- Sutherland, O., Stramaccioni, D., Benkhoff, J., Wallace, N., Feili, D., Rocchi, A., & Jehn, R. (2019). BepiColombo: ESA’s Interplanetary Electric Propulsion Mission to Mercury. https://electricrocket.org/2019/824.pdf [↩] [↩] [↩]

- Gray, H., & Sutherland, O. (2013). Development and Qualification Status of the Electric Propulsion System for the BepiColombo Mission. https://electricrocket.org/IEPC/91ijrwc3.pdf [↩]

- Ronco, V. D. (2011). The Challenge of Design and Develop a Dual-mode Propulsion System for BepiColombo ESA Exploration Mission to Mercury. https://doi.org/10.2514/6.2011-5833 [↩] [↩]

- Wallace, N. (2018). BepiColombo Mission and the Solar Electric Propulsion System (SEPS). https://epic-src.eu/wp-content/uploads/LS.1.6.-Neil-Wallace-EPIC-BepiColombo-presentation-B.pdf [↩]

- Wallace, N. (2018). BepiColombo Mission and the Solar Electric Propulsion System (SEPS). https://epic-src.eu/wp-content/uploads/LS.1.6.-Neil-Wallace-EPIC-BepiColombo-presentation-B.pdf [↩]

- Ariane Group. (n.d.). 10 N Bipropellant Thrusters. Www.space-Propulsion.com. https://www.space-propulsion.com/spacecraft-propulsion/bipropellant-thrusters/10-bipropellant-thrusters.html [↩]

- National Institute of Standards and Technology. (2025). 1.3.5.17. Detection of Outliers. Nist.gov. https://www.itl.nist.gov/div898/handbook/eda/section3/eda35h.htm?utm_source=chatgpt.com [↩]